Odoo for Apparel & Fashion

Calculate the Costs. Plan Confidently

Explore our proven Odoo delivery models

- Odoo installation and setup

- Basic configuration of core modules

- Data import templates

- Employee training (2 sessions)

- Odoo installation and configuration based on business requirements

- Data import support

- Business process customization

- Personalization: custom layouts, etc.

- Employee training

- Everything from the Business Pack

- Customization of Odoo modules

- E-commerce integration

- API integration with external systems

- Automation of complex business processes

- Large-scale data migration

- Analytics integration

- Dedicated project manager

- Dedicated Odoo experts (developers, consultants, project managers)

- Ongoing system optimization and feature enhancements

- Advanced customization and automation

- Continuous data imports and integrations

- AI-driven analytics & forecasting tools implementation

- Security updates and performance optimization

- Priority support and troubleshooting

Does your company currently have an ERP system?

How many employees or contractors will need access to the Odoo system?

What areas do you want to improve within your organization?

What problems are you looking to solve?

Odoo ERP Software for Apparel Businesses

Operational Gaps in the Apparel Industry that Odoo Can Fix for You

Browse Our Odoo Services for Your Apparel Business

Transform Fashion Operations with Odoo

Core Odoo Modules Your Business Needs

Expand Odoo with Third‑Party Apps

Business-Ready Custom Modules

Why Leading Fashion Brands Choose Odoo

What our clients say about us

Our clients journeys

Who we are

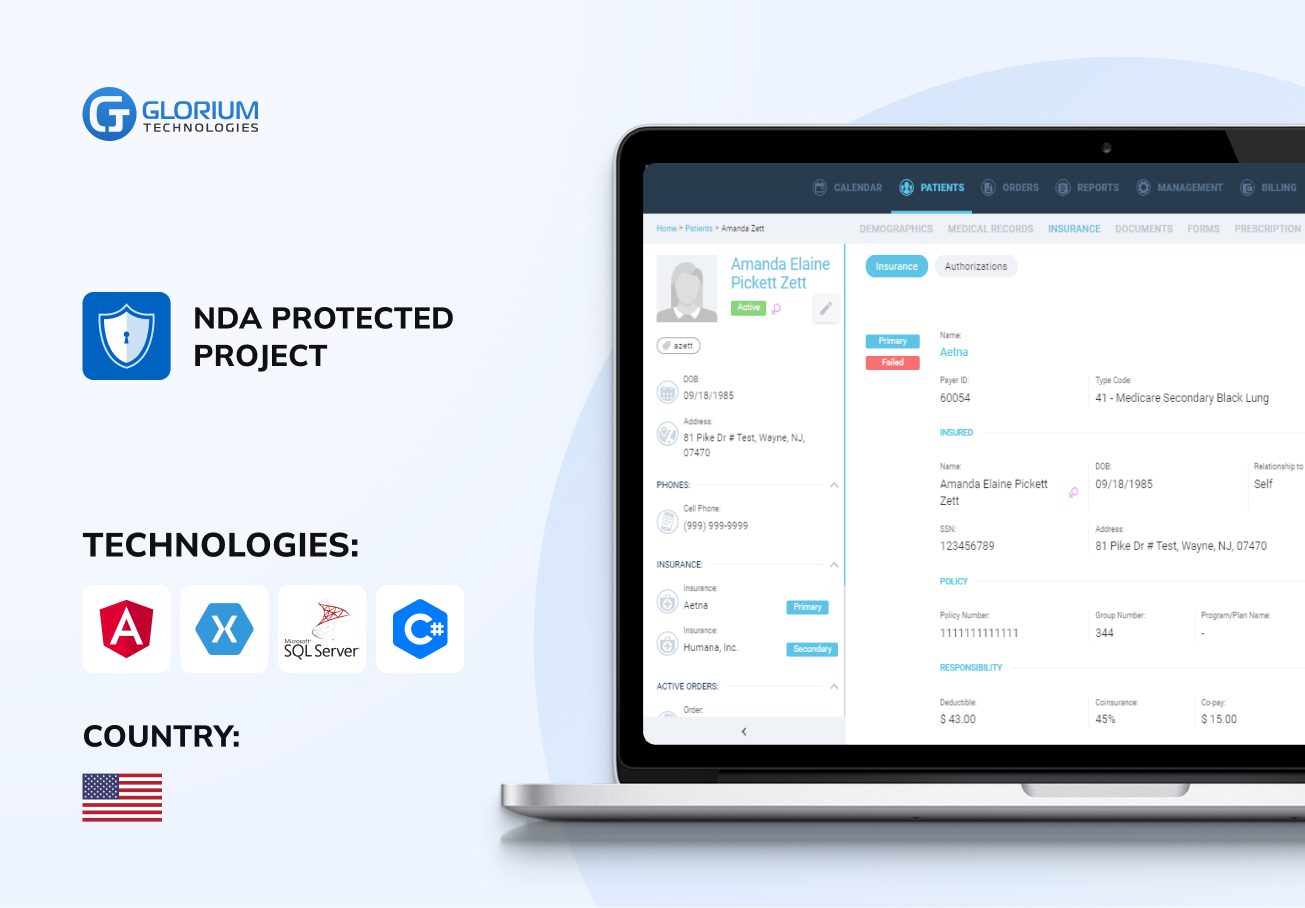

About usGlorium Technologies is a full-cycle app & software development company which covers specific client business needs and manage them with the help of the best possible technology solutions.

Since 2010, we have been inventing digital breakthroughs, helping startups and businesses come out on top in their markets.

Why choose us

Let's Connect!

Why Growing Brands Choose Odoo for Apparel Business Success

Apparel manufacturers face pressure to meet customer expectations for rapid trends, green practices, and innovation. You need to find a way to reduce waste and elevate quality while lowering your environmental footprint. It becomes clear that those embracing smart textiles, next‑gen manufacturing, and renewable resources will shape the industry’s next chapter.

The apparel manufacturing industry is now one of the most dynamic sectors globally, valued at over $1.84 trillion. Yet some brands still struggle with fragmented business processes, slow order management, and poor supply chain visibility. They can’t always vouch for timely delivery or uncompromising order fulfilment, which affects customer satisfaction.

The ERP system with integrated supply chain modules is a tried-and-tested way to reduce production lead time by up to 37% and improve schedule adherence by as much as 30%. Odoo’s modular structure and comprehensive functionality make it an ultimate solution for apparel companies interested in reshaping manufacturing processes and improving customer relationship management.

The Apparel Industry’s Need for Unified Business Operations

Managing production across multiple disconnected tools in the fast-paced fashion market creates nonstop inefficiencies. Real change requires an integrated platform that unifies business operations and provides real‑time data analysis. Continue relying on fragmented systems for order, stock, and project management, and you’ll face:

- Inaccurate stock levels

- Delayed production processes

- Poor supply chain visibility

- Slower timely completion of orders

Apparel business owners using ERP solutions like Odoo can expect to achieve greater efficiency and up to 23% faster order processing. They can also improve delivery time by 20% thanks to effective planning and enhanced productivity. You can manage every stage—design, sourcing, manufacturing, distribution, sales, and customer service—through one intuitive interface powered by the same real‑time data.

Efficient equipment management for timely completion

Suppose you are operating in the textile industry. In this case, unplanned downtime may cost anywhere from $10,000 to $50,000 per hour. The final expense will depend on plant size, location, and processes. Large facilities operating at peak production may hit the upper end of this range in high‑cost regions. Efficient management and equipment maintenance is fundamental for extending machinery lifespan.

If you implement Odoo’s maintenance module, you’ll be able to monitor and record detailed machine service histories. This proactive approach may cut equipment breakdowns by around 25% and improve operational efficiency across your production processes.

Optimizing supply chain management for timely delivery

Your ability to meet customer demands often depends heavily on the well-thought-out management of your supply chain. Every step must be coordinated to prevent delays and protect profitability, from sourcing raw materials to shipping finished goods. Yet many apparel companies and textile manufacturers rely on tools that slow down order management processes and create gaps in inventory management, increasing the risk of late deliveries.

Open source ERP software connects manufacturing processes, order management, financial transactions, and quality control in one place. Odoo ERP software offers real-time stock tracking and improved procurement, production, and logistics collaboration. As a result, you can plan more effectively and achieve growth, whatever market shifts take place.

The system supports medium-sized businesses and large enterprises alike. You can capitalize on exceptional Odoo services and flexibility, improve cash flow, and ensure timely delivery.

Key supply chain advantages with Odoo ERP are:

- Real-time stock tracking for informed decisions on replenishment

- Automated reordering for raw and semi-finished products

- Integrated shipping and carrier tracking

- Centralized financial management

- Stronger customer relationship management

- Easy connection with repair management and maintenance schedules for equipment uptime

Let Glorium Technologies Tailor Odoo ERP for You

Modern, flexible systems are key for future-oriented apparel brands looking to boost turnover. Rigid software forces your business to function within the limits you haven’t set. As an official Odoo partner, Glorium Technologies can configure the ERP around your operations to match your exact workflows. We adapt every module from sales and inventory to finance and customer management to fit your goals.

Our team ensures Odoo helps improve efficiency across departments and cut down on manual work. With better system integration, you’ll also improve communication between teams and keep your business running smoothly. Whether you’re scaling up or refining current processes, we make Odoo work for you—faster, smarter, and built for measurable impact. Do you have any questions or concerns? Schedule a free consultation and let’s talk.

More From Glorium Technologies

FAQ

What equipment management features does Odoo ERP offer?

Odoo ERP helps businesses streamline operations by offering built-in tools for efficient equipment maintenance. A dedicated module has features like tracking machine performance, scheduling maintenance, logging repairs, and linking equipment to specific production orders. These capabilities reduce downtime, extend asset lifespan, and support better planning across manufacturing and maintenance teams.

Can Odoo’s customer relationship management tools be adapted to complex sales cycles?

The system supports multi-stage pipelines, custom workflows, and automated follow-ups. It contributes to improved collaboration, tracks long-term interactions, and manages opportunities precisely—making it ideal for both B2B and B2C relationship-driven sales environments.

How does Odoo ERP improve production planning and control in manufacturing?

Streamlined manufacturing order management allows teams to track orders, manage work centers, and monitor progress in real time. It connects production with inventory and procurement, reducing delays, minimizing waste, and ensuring efficient coordination from raw materials to finished goods.