The Odoo 18 Implementation That Rebuilt Operations End to End

Glorium Technologies implemented Odoo 18 Enterprise, hosted on Odoo.sh, combining manufacturing, sales, inventory, quality control, projects, and finance into one system. Key modules included:

- CRM & Sales: Full sales pipeline management for B2B and B2C with KPI tracking and commission setup.

- Manufacturing: Multi-level BoMs, automated work orders, and tracking of scrap and defects.

- Inventory + Barcode: Real-time visibility across two warehouses with lot/serial number tracking.

- Quality: Checks tied directly to purchase and work orders.

- Project: Full cost tracking from quote to installation.

- Purchase: Smart reordering based on lead times and stock levels.

- Accounting: Integrated with QuickBooks for seamless financial reporting.

- Website + eCommerce: A new modern store connected with inventory and customer accounts.

What Changed After Moving to a Fully Integrated Odoo 18 Enterprise System

After our partnership, the client achieved impressive results, with key modules implemented that streamlined operations and boosted overall efficiency.

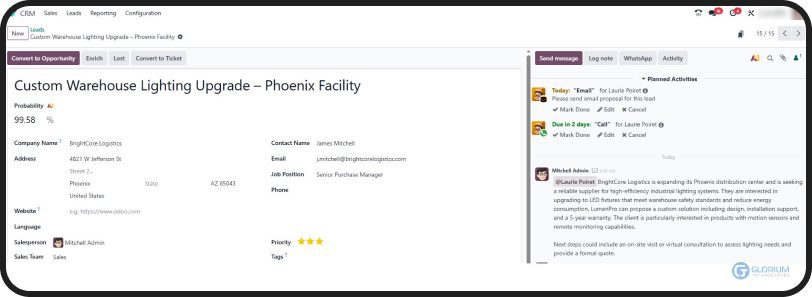

CRM

- Capture leads automatically from emails and the website

- Store all customer communications in Chatter (no more lost emails)

- Track the full journey from first contact to successful sale

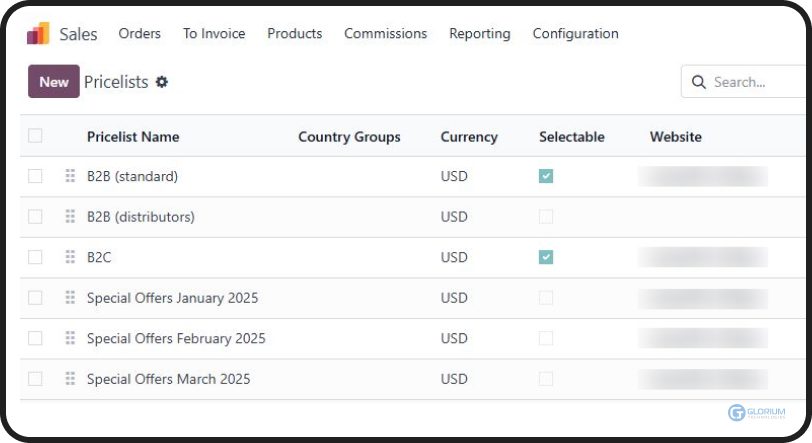

Sales

- Manage B2B and B2C sales, both online and offline

- Track KPIs by sales manager

- Set up sales commissions

- View the full sales pipeline and order history

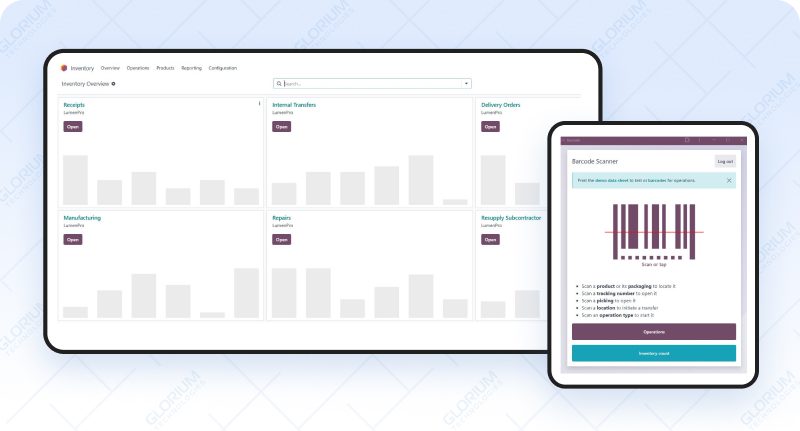

Inventory + Barcode

- Address-based storage across two warehouses

- Lot and serial number tracking for every component and product

- Returns management (warranty and non-warranty)

- Shipping via FedEx, UPS, or in-house delivery

- Label generation for boxes and pallets

- Real-time stock updates using barcode scanners

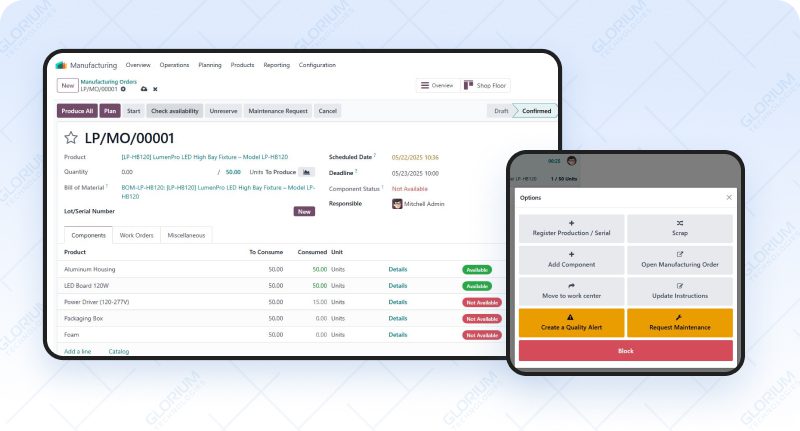

Manufacturing

- Multi-level BoMs

- Plan and schedule work orders

- Integrate directly with inventory for material availability

- Track defects and scrap during production

- Support both made-to-order and made-to-stock workflows

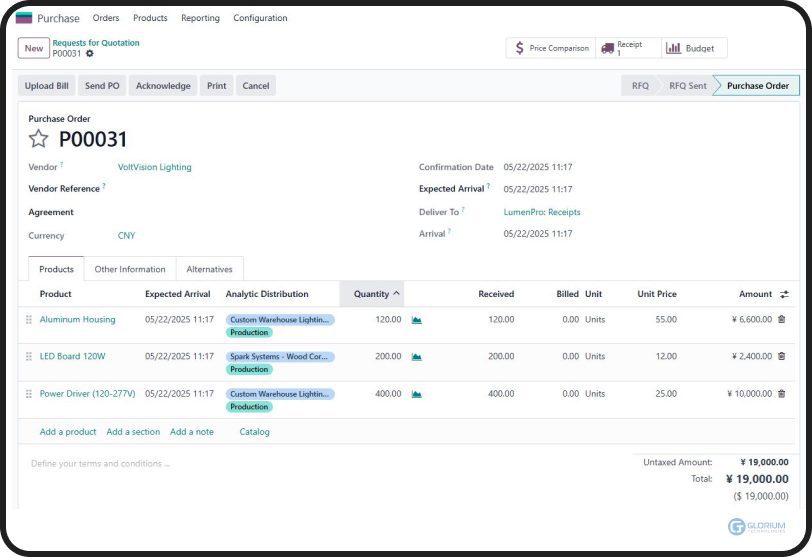

Purchase

- Set up vendor lead times and automatic reordering

- Link purchase orders to inventory and quality control

- Multi-currency support (most supplies come from China)

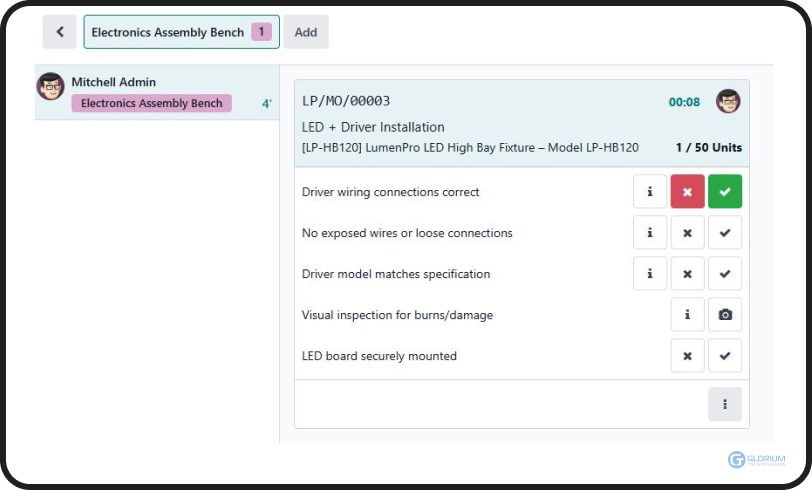

Quality

- Quality checks for incoming components and finished products

- Quality statistics for each component

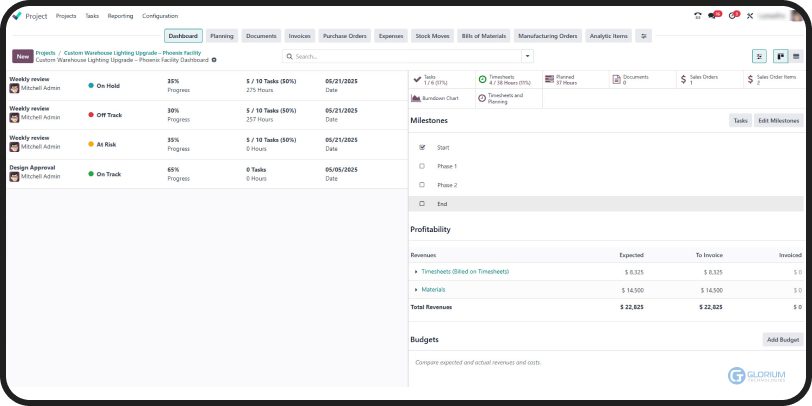

Project

- Manage custom lighting projects from quote to installation

- Track budgets, planned vs. actual costs, and profitability

- Assign tasks and track project milestones

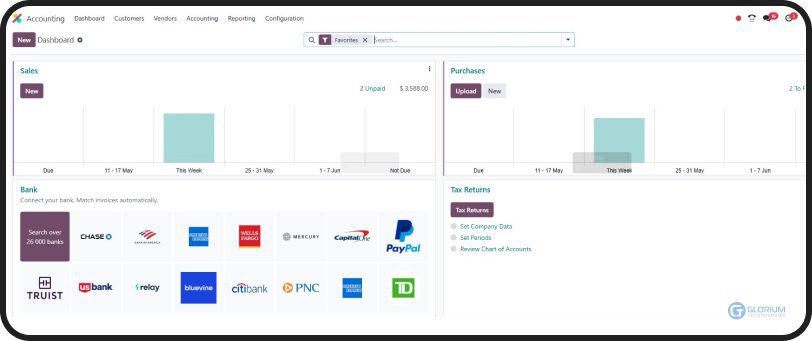

Accounting + QuickBooks Integration

- Sync customer invoices and vendor bills with QuickBooks

- Use Odoo for cost tracking and analytical reporting

- Keep financial operations aligned with project and sales data

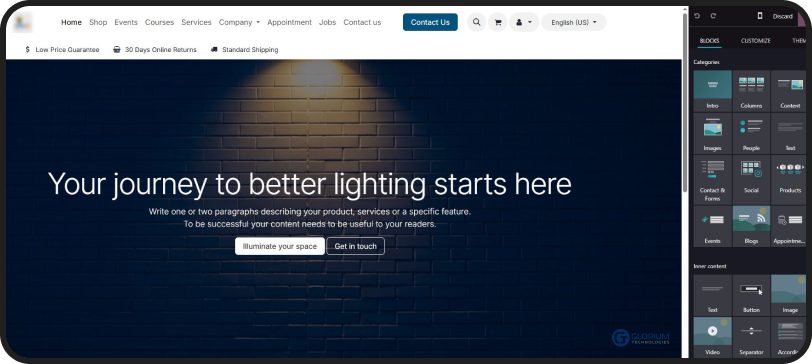

Website + eCommerce

- New modern online store integrated with sales and inventory

- Accept both B2B and B2C orders

- Customer portal for order tracking, returns, and invoices

- Vendor portal for supplier invoices and payments tracking

Future Expansion (Planned for Next Year)

With their core operations now automated and streamlined, the client plans to expand further by implementing

- PLM (Product Lifecycle Management) for version control of lighting designs

- Fleet to manage delivery vehicles and internal transport

- Field Service for on-site installations and service visits

- Planning for shift scheduling and production staffing

- Employees, Timesheets, Time Off to handle HR operations

- Dashboards for real-time performance tracking

- Marketing Automation to engage customers and leads

This all-in-one solution unifies every department, cuts down manual effort, boosts accuracy, and lays the foundation for future growth—with the flexibility to scale as the business evolves.

How a Three-Stage Odoo Rollout Delivered Long-Term Stability

MVP Launch (Weeks 1–16)

- Focus: Core production and supply chain processes

- Modules: Manufacturing, Quality, Inventory, Purchase

- Goal: Automate production planning, implement quality checks, organize warehouse operations (including barcode scanning and shipping), and streamline procurement

- Training: Guidance for sales reps, project managers, and the finance team

Phase 1 (Weeks 16–24)

- Focus: Sales and customer operations

- Modules: Sales, CRM, Project + Budgets

- Goal: Centralize communication, manage B2B/B2C sales, track sales KPIs and commissions, and monitor project profitability

- Training: Guidance for sales reps, project managers, and finance team

Phase 2 (Weeks 24–32)

- Focus: Online presence and financial integration

- Modules: Website + eCommerce, Accounting with QuickBooks integration, Minor Improvements and customizations

- Goal: Launch new online store, link financials with QuickBooks, polish workflows based on real usage

- Training: eCommerce admin training and accounting team onboarding

Each phase includes detailed user instructions, training sessions, and review checkpoints to ensure smooth adoption and value realization.

Where the Lighting Manufacturer Saw the Biggest Gains

Inventory Accuracy & Warehouse Efficiency

Barcode-driven inventory across two warehouses increased accuracy by over 90%, eliminating 16% a year in stock losses and shipping errors.

Production Agility & Quality Control

Custom and standard workflows now operate side-by-side. Quality checks tied to orders reduced defect rates by 35%, saving rework costs and improving delivery timelines.

Customer Experience & Sales Growth

Centralized CRM and a modern B2C eCommerce store improved responsiveness and increased online sales conversion by 18%.

Shipping Automation

Integrated label printing and multi-carrier support (FedEx, UPS, in-house) now save 20+ hours per month previously spent on manual tasks.

Project Profitability Insights

Each lighting project now has clear visibility into costs, margins, and timelines—fueling better quoting and resource allocation.

Accounting Alignment

Odoo–QuickBooks integration ended double data entry, eliminating monthly reconciliation errors and saving over 15% a year in accounting overhead.