ERP Supply Chain Management: Role, Benefits, and Use Cases

The global ERP market was valued at approximately $92.6 billion in 2025 and projected to reach $106.22 billion by 2026. The supply chain segment has emerged as the fastest-growing category here, driven by an urgent organizational need for real-time data and optimized logistics. Despite this momentum, a significant integration gap remains. While over 50% of retailers cite supply chain disruptions as their primary challenge for 2025, only 17% have fully integrated their ERP systems across all departments.

In this article, we will discuss what ERP is, the benefits of ERP in supply chain management, and the top ERP software we recommend to our clients at Glorium Technologies.

Content

The role of ERP in supply chain management is defined by its capacity to:

Historically, procurement, warehousing, production, and finance departments operated as isolated functional silos. Each maintained independent records and software applications. This fragmentation invariably led to data silos. This is when critical information regarding inventory depletion or demand surges remained trapped within specific departments. Significant delays and systemic errors in strategic decision-making were present.

ERP systems mitigate these inefficiencies by establishing a single source of truth. Every stakeholder across the organization has access to the same up-to-date information.

While the terms Enterprise Resource Planning (ERP) and Supply Chain Management (SCM) are frequently used in tandem, they represent distinct software categories with differing focuses, functional depths, and architectural goals.

| Feature Comparison | ERP Systems | SCM Solutions |

| Primary Objective | Internal process synchronization and resource optimization. | External network coordination and logistics optimization. |

| Functional Breadth | Broad (Finance, HR, CRM, SCM, PM). | Specialized (Sourcing, Logistics, Demand Planning). |

| Data Architecture | Single, unified database for the entire company. | Distributed data requiring integration with multiple partners. |

| Decision Horizon | Strategic and operational internal management. | Tactical and operational supply chain planning. |

| Typical Users | All employees across the enterprise. | Supply chain managers, logistics teams, and external partners. |

| Transaction Focus | Task-based (Invoicing, Payroll, Stock entry). | Relationship-based (Vendor terms, Contract management). |

Many modern enterprises choose a hybrid approach. First, they implement an ERP platform, such as Odoo or SAP, to manage their core internal operations. Then, they integrate specialized SCM modules or best-of-breed software to meet highly complex requirements, such as international freight forwarding or advanced AI-driven demand forecasting.

Nevertheless, let`s investigate how SCM and ERP platforms differ in terms of 2 distinct characteristics.

The primary distinction between the two lies in their scope. ERP systems are designed for comprehensive, internal organizational integration. Their strategic focus is horizontal, aiming to connect every department: Human Resources, Finance, Sales, Marketing, Production, etc. The ERP’s goal is to optimize the internal operations of the company by providing a full view of resources and business processes.

SCM solutions, conversely, have a narrow and deep focus on the external supply chain. They are built for vertical alignment and facilitate the flow of goods, data, and finances between a company and its external partners. Here, we mean suppliers, distributors, 3PL providers, and end-customers.

While an ERP manages the internal resources required for production planning, an SCM system manages the intricate relationships and logistics required to move products through the entire global network.

ERP systems are generally transactional and task-based in nature. They excel at recording and managing day-to-day operations, such as processing payroll, generating invoices, recording inventory movements, etc. While they include supply chain features, these are often designed to harmonize with other business functions rather than provide the deepest possible level of supply chain optimization.

SCM systems are specialized tools designed for planning and execution. They often contain advanced mathematical models for demand sensing, multi-echelon inventory optimization, and global transportation network design.

In this context, SCM systems’ capabilities go beyond the standard capabilities of an ERP module.

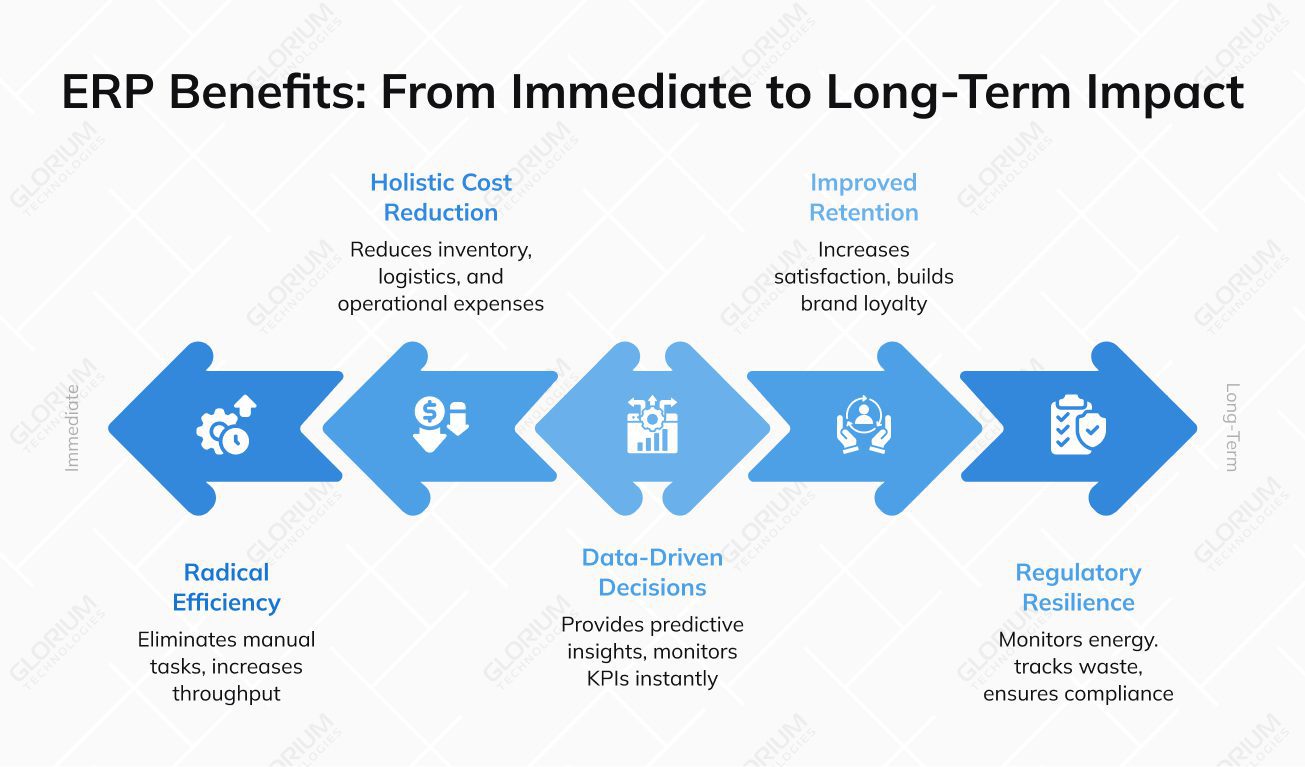

The integration of ERP into a supply chain strategy is a strategic transformation that yields measurable benefits in efficiency, cost management, and customer relations. By providing a digitized framework for complex operations, ERP systems allow you to have proactive supply chain management.

The most immediate benefit of an ERP-driven supply chain is the elimination of manual, error-prone, routine tasks. 5-10 years ago, before ERP mass adoption, the delay between a sales event and a procurement action could be days, as information was manually transferred between spreadsheets and systems. ERP systems automated these workflows, and now, they ensure that data moves fast.

Automating routine tasks extends to document generation, where the system can automatically produce invoices, packing lists, and shipping labels. It reduces the administrative burden on warehouse staff. In the manufacturing sector, ERP systems automate production scheduling based on real-time resource availability. They ensure that labor and machinery are used at peak efficiency.

So, ERP implementation brings radical operational efficiency. You can do more with fewer resources, increasing throughput and profitability.

Cost reduction in an ERP-enabled supply chain occurs across multiple levels. By providing real-time visibility into inventory, you can reduce your “buffer” stock, which is often kept as a safeguard against data inaccuracies. This optimization reduces operational costs, including the expense of:

So, logistics costs are reduced through intelligent route planning and load optimization features that minimize fuel consumption and delivery times. Centralized procurement modules allow for better management of supplier contracts and the identification of bulk-buying opportunities. Automated financial data monitoring helps eliminate duplicate payments and identify early-payment discounts. As you can see, ERP implemented with the right partner can pay itself tenfold.

The transition from guesswork to data-driven strategy is perhaps the most profound benefit of ERP. Modern systems use historical data and ML to provide predictive insights that were previously inaccessible. Demand forecasting allows companies to anticipate market shifts before they occur.

Real-time reporting and analytics dashboards allow supply chain managers to monitor performance against critical KPIs (key performance indicators) instantly. If a bottleneck appears in a specific warehouse or if a supplier’s on-time delivery rate drops, the system provides the visibility needed to identify the root cause and implement a solution immediately.

Customer expectations for speed, accuracy, and transparency have reached an all-time high. An ERP-driven supply chain ensures that these expectations are met consistently. By integrating sales, inventory levels, and logistics, you can provide customers with accurate information regarding product availability and delivery timelines.

When orders are processed without error and delivered on time, customer satisfaction naturally increases. This leads to higher retention rates and brand loyalty. Furthermore, the integration of CRM data within the ERP allows customer service teams to access full order histories instantly.

A growing focus for modern enterprises is the intersection of supply chain efficiency and environmental responsibility. A study conducted by the IBM Institute for Business Value and SAP indicated that organizations with deeply engaged ERP implementations consistently outperform their competitors in both environmental and financial outcomes. ERP systems provide the technological framework for:

From a regulatory standpoint, ERP systems provide the audit trail necessary for compliance in highly regulated industries like pharmaceuticals, food and beverage, aerospace, etc. Automated documentation and batch tracking ensure that the company can quickly respond to regulatory inquiries or manage product recalls with surgical precision. This helps in mitigating both legal and financial risks.

The benefits of ERP are proven through practical, industry-specific use cases. For example, we at Glorium Technologies delivered plenty of efficient supply chain management solutions. By using the diverse modules within a system like Odoo, you can optimize every link throughout supply chain processes.

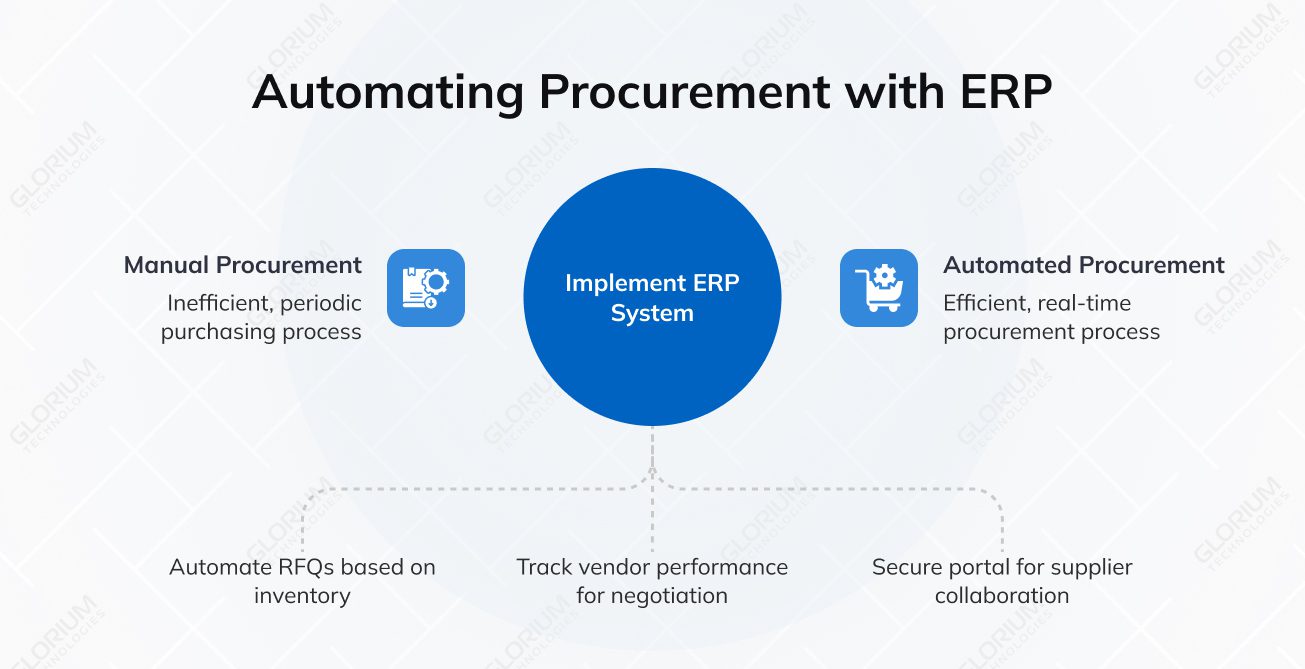

One of the most effective ways to use ERP is to automate the procurement lifecycle. Instead of manual purchasing based on periodic reviews, the system uses real-time inventory data to trigger actions. How this works:

For example, we have implemented a similar project for one of our clients. We achieved 2x faster supplier response with Odoo Construction project management. We recommend you read the case study if you’re interested in how ERP can fix the issues disconnected systems create.

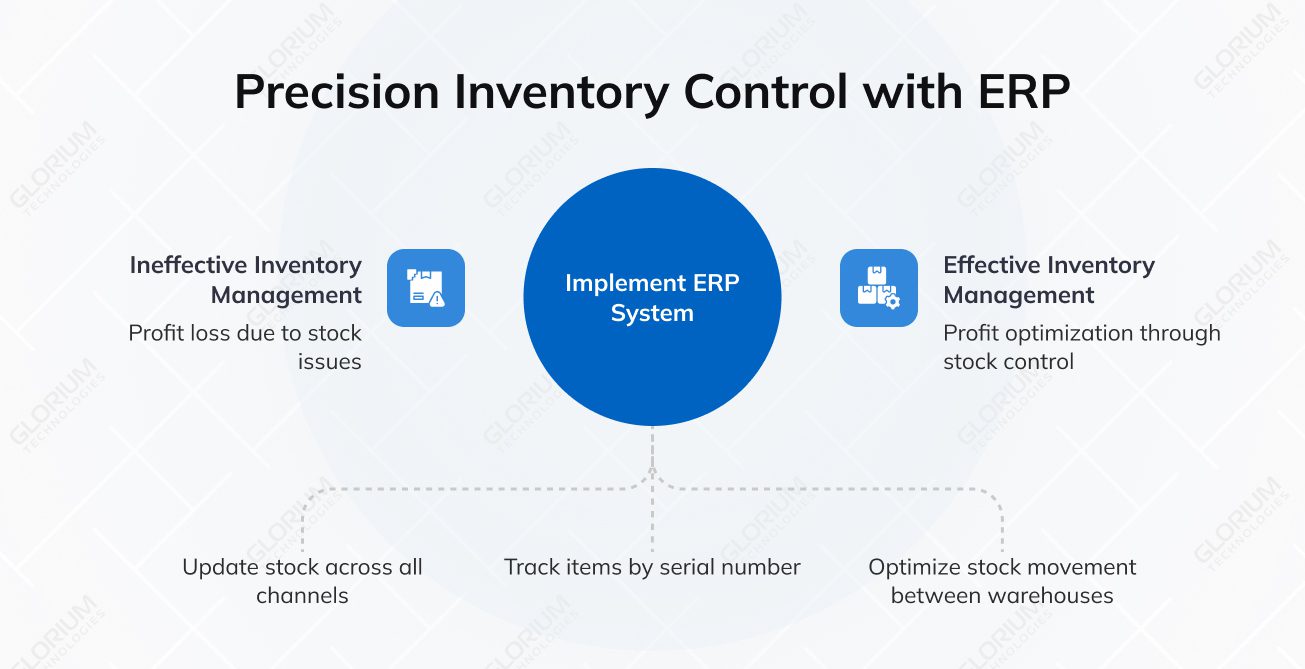

In retail and distribution, advanced inventory management capabilities are the difference between profit and loss. ERP systems provide granular control over stock across vast networks. How this works:

We have implemented a similar project and cut stockouts and overstocking by 80% for our client.

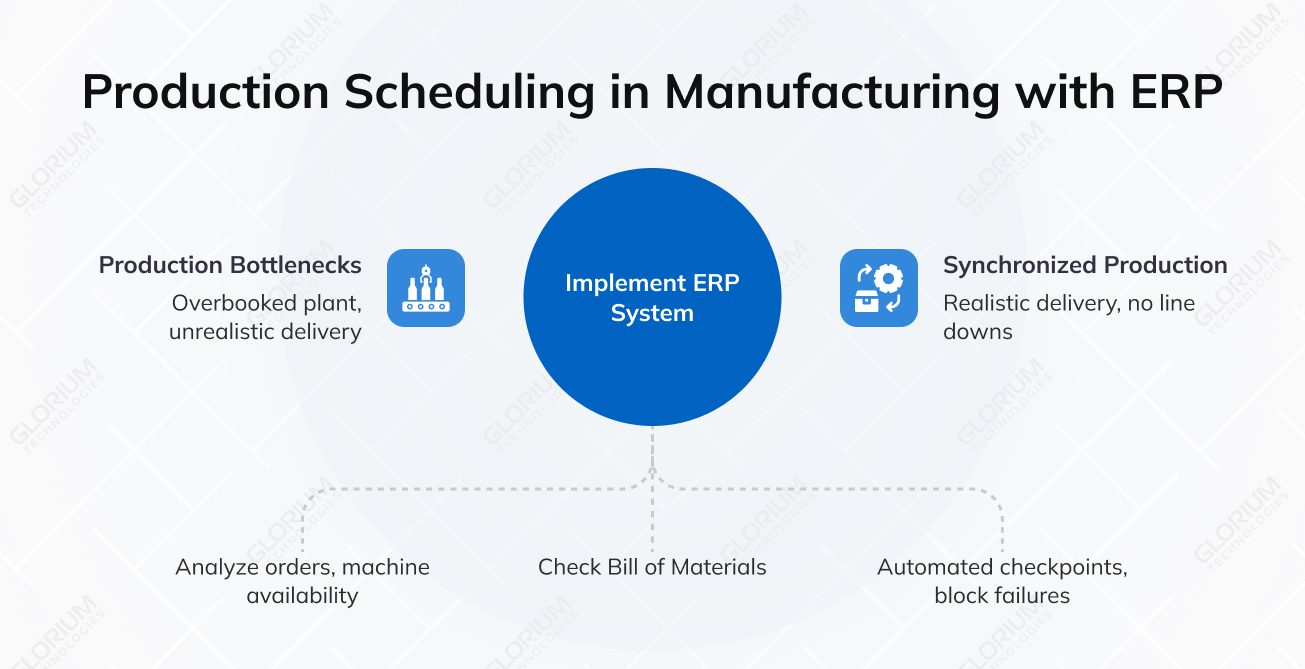

For manufacturers, the ERP is the primary tool for synchronizing production with the entire supply chain. With it, you can schedule production much more easily thanks to scenario planning capabilities. How this works:

We recommend you read our case study on how Odoo food distribution software delivered a 90% reporting time drop.

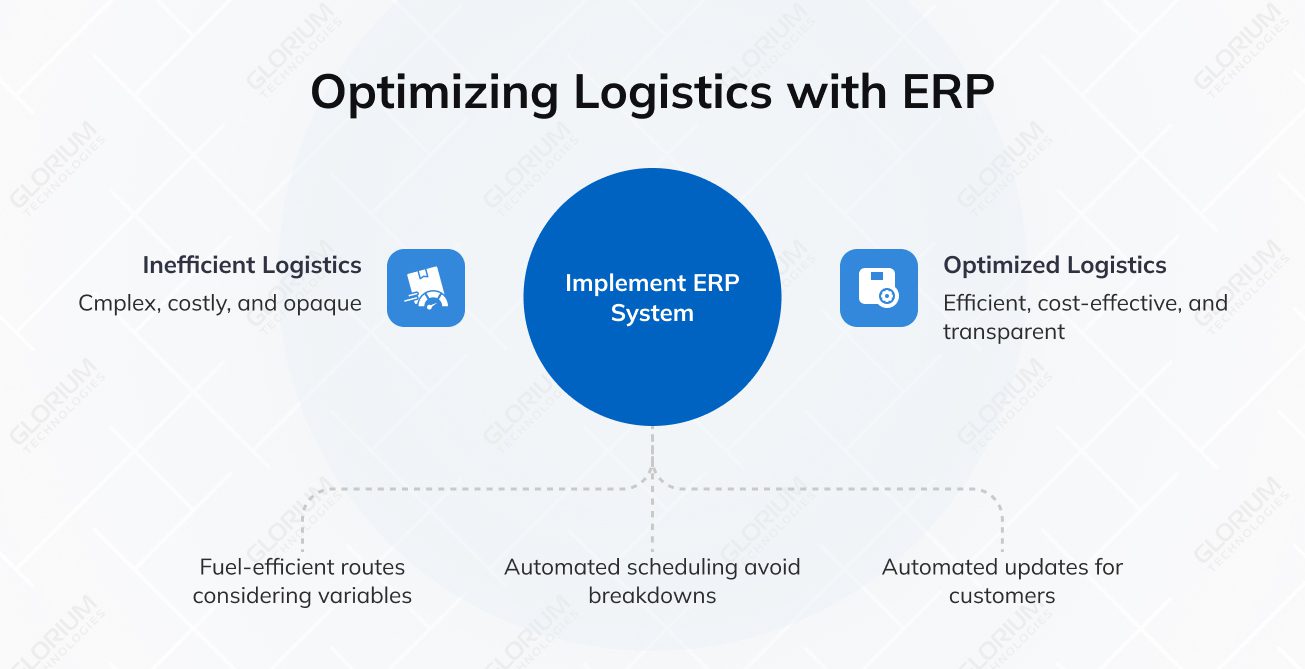

Logistics is a complex puzzle that ERP systems help solve through data analysis and real-time connectivity. We have seen many times how Odoo Logistics helped fix supply chain disruptions. How this works:

The successful implementation of a new ERP system in all these scenarios requires the involvement of a professional team. Glorium Technologies, for example, is an official Odoo partner, implementing all these scenarios and many others thanks to the modular capabilities of Odoo.

Founded by Fabien Pinckaers, it evolved from TinyERP to OpenERP before becoming Odoo. Quick facts:

Odoo is particularly well-suited for supply chain operations due to its flexibility and comprehensive application ecosystem. So, let`s discuss why we recommend business leaders pay attention to one of the best cloud ERP solutions.

Odoo’s defining characteristic is its modularity. You can start with a single module, such as “Inventory”, and add others only as they are needed (“Purchasing”, “Manufacturing”, “Accounting”, etc.). Every module is built on the same foundation. As a result, they are natively integrated and share a single database.

Odoo allows for a “start small, scale fast” approach. Your businesses can avoid the high upfront costs and overwhelming complexity associated with traditional ERP implementations. You can check our article about Odoo modules to dive deeper into its capabilities.

As an open-source platform, Odoo grants you the freedom to modify the software’s code to fit your exact specifications. This is invaluable for companies with unique supply chain workflows that do not fit into “standard” software molds. Furthermore, Odoo boasts an app store with over 40,000 community-developed applications. You can easily get pre-built solutions for almost any industry-specific challenge.

Odoo is designed to grow alongside the enterprise. It supports multi-company, multi-warehouse, and multi-currency configurations. This is why it is an ideal choice for businesses expanding internationally.

Its backend is powered by PostgreSQL. This database architecture is capable of handling thousands of users and massive supply chain data volumes without compromising performance.

The total cost of ownership (TCO) for Odoo is significantly lower than for competitors like SAP or Oracle. There are no hidden licensing fees. Moreover, the phased implementation model allows companies to achieve a high ROI much faster.

From our experience, we see a 62% reduction in licensing and operational expenses after migrating to Odoo for our clients. Our Odoo case studies from the Glorium Technologies article covers 8 vivid examples of Odoo implementation results.

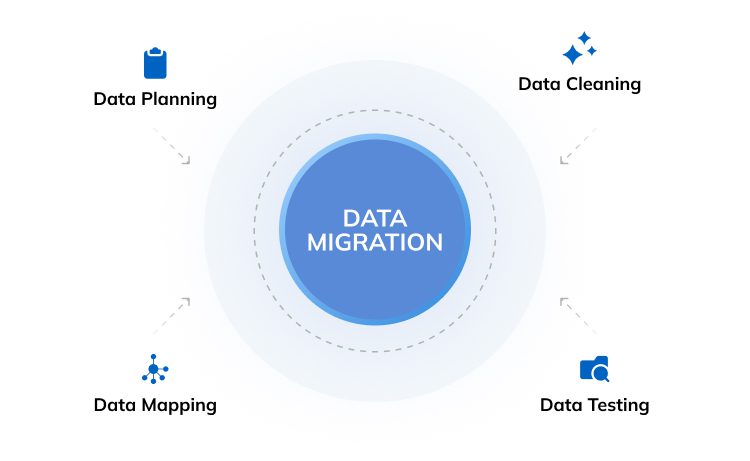

Choosing the right software is only half the battle. The other half is selecting an implementation partner with the expertise to execute your vision. Glorium Technologies is a Certified Odoo Partner with a deep specialization in logistics and supply chain management.

Glorium Technologies understands that a standard “out-of-the-box” setup rarely meets the complex needs of a modern supply chain. Our team of experts and consultants specializes in creating custom modules for:

At Glorium Technologies, you can implement Odoo with minimal disruptions to your business workflows, migrate from a legacy system, integrate third-party applications, and get employee training and support to ensure a 98% adoption rate.

We welcome you to explore our case studies. Book an intro call with our experts, and let’s map your Odoo ERP journey.

For mid-market and rapidly scaling companies, Odoo is a top choice because of its modularity, user-friendly interface, and cost-effectiveness compared to legacy “heavy” systems. For large, multi-national corporations, SAP S/4HANA remains the leader due to its advanced in-memory processing and AI-powered business intelligence. Microsoft Dynamics 365 Business Central is a close competitor to Odoo. It is an excellent ERP software for companies outgrowing basic accounting software that need deep integration with the Microsoft ecosystem and AI-powered automation (via Copilot). If you’re looking for a trusted partner for BC implementation, Glorium Technologies is an official Microsoft Dynamics 365 Business Central partner.

Enterprise resource planning refers to a centralized system that integrates all supply chain activities. It glues together different departments like buying, tracking stock, handling orders, and managing trucks. This allows logistics providers to achieve real-time visibility into their operations and optimize the movement of goods.

Yes, in most modern business management ecosystems, Supply Chain Management is a core module within a broader ERP platform. While some companies use “best-of-breed” standalone SCM software for extremely specialized needs, the trend is toward using integrated ERP systems. Why? They handle SCM natively to ensure all data is synchronized in one place.

These systems serve different but complementary roles. ERP is the foundation that integrates internal processes such as finance and production. CRM is a tool focused on managing customer data, leads, and service requests. SCM is a tool that manages the external relationships with suppliers and the logistics of moving goods. An ERP system like Odoo integrates all three into a single system.

Commonly used ERP systems in the supply chain include:

Industry-specific solutions also exist, like Epicor Kinetic for manufacturing and Infor CloudSuite for logistics. To find more, you can check our article about the 7 best ERPs for manufacturing businesses.

In SCM, ERP systems are used to automate and optimize the entire product lifecycle. This includes:

To dive deeper into this topic, see the list of the best ERPs for SMEs in 2026.

The ERP advantages include:

The ERP disadvantages are primarily centered around high initial setup costs, the complexity of the implementation process, potential resistance to change from employees, and the high level of technical expertise required to migrate and maintain the system. Partnership with Glorium Technologies, a certified Odoo implementation partner, mitigates these risks.