How Odoo 18 Enterprise Transforms Operations Across Industries: Real Case Studies from Glorium Technologies

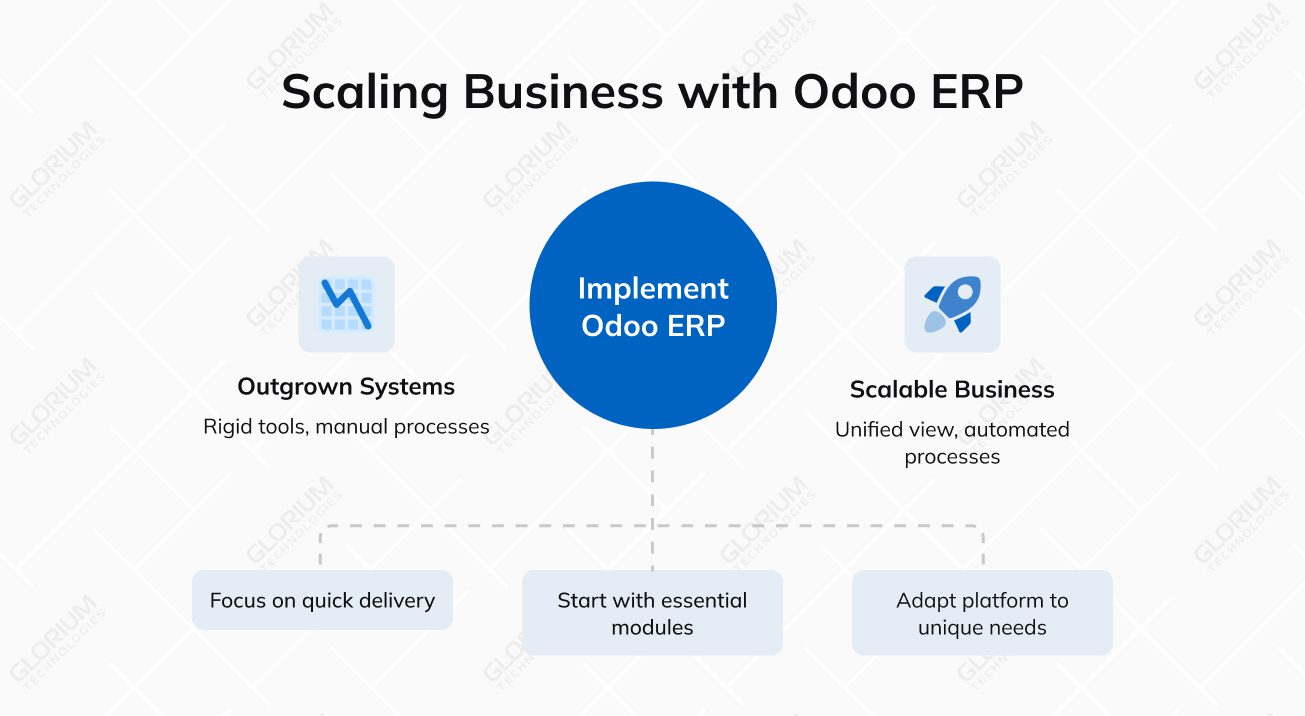

Reaching new heights with your business is an incredible achievement. However, success often reveals new friction points: your current tools start to feel rigid, manual processes consume valuable time, and obtaining a clear, unified view of your operations becomes a project in itself.

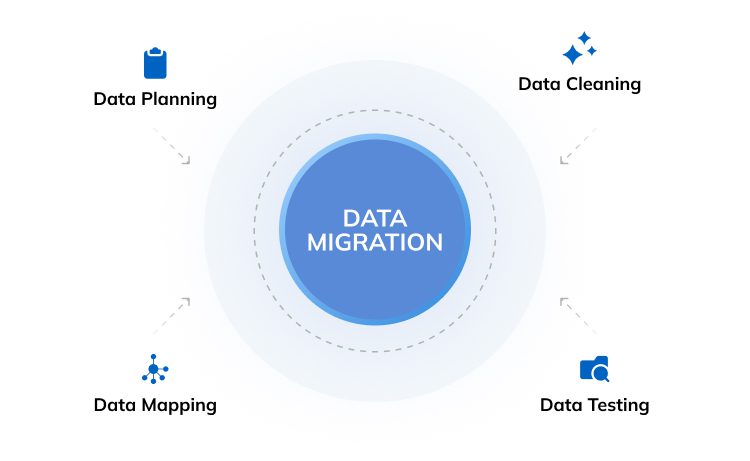

Nothing’s broken—you’ve simply outgrown the systems that got you here. And as a solution to such issues, growing companies often invest in modern ERP systems. Odoo 18 Enterprise is designed for this exact scenario. It’s a flexible, all-in-one platform that can replace a patchwork of applications with a single solution.

It’s a modern choice with a modular design that helps you get started with what you need now (a CRM, inventory, accounting, etc.) and add new capabilities as your business grows. It guarantees that when you reach new heights, your software can scale alongside.

So, how do you get started with Odoo?

In our experience at Glorium Technologies, the most successful implementations begin with a single, high-impact goal. We help pinpoint that goal, focus on a quick delivery, and build a solid foundation for the future.

But don’t just take our word for it. The accurate measure of a platform’s versatility is seen in the real-world problems it solves. In this article, we will explore Odoo case studies that show how a single platform can be expertly customized to unique business needs:

Content

Manufacturers often hit a point where spreadsheets and legacy tools can’t keep up with demand. This section highlights how Odoo 18 Enterprise streamlines complex workflows—like quoting, production planning, and quality control—to help industrial companies move faster, reduce errors, and gain full visibility across their operations.

For a well-established American steel manufacturer, quality was never the issue. Their products were trusted for major construction projects nationwide. But behind the scenes, their operational foundation was strained. This implementation is one of our most impactful Odoo ERP case studies, demonstrating the platform’s power in complex manufacturing.

For over two decades, the company had seen successful growth, but its internal processes were still running on a patchwork of legacy systems and manual work. They noticed a glaring challenge in their sales quoting process—A single quote for a customer required manual management of over 700 different parameters in sprawling Excel spreadsheets. For a large company, such an approach is incredibly time-consuming and leads to errors and disruptions in production.

Additionally, they had to deal with:

The company soon realized that to continue growing, they needed to adopt a unified system that could handle their complexity. That’s when they reached out to us at Glorium Technologies.

Our experience shows that an off-the-shelf solution rarely works for companies with unique needs and workflows. Our first step was to listen and learn about the intricacies of the business, enabling us to build and offer a phased Odoo implementation, typical of all our Odoo case studies.

| Metric | Improvement | Outcome |

| Order Conversion Speed | +30% Faster | Streamlined workflow accelerated order-to-fulfillment. |

| Quotation Preparation Time | –50% Reduction | Automated templates eliminated manual spreadsheet work. |

| Revision Visibility | 100% Transparency | Full traceability for every specification change. |

| Production Quality | Significantly Fewer Rejections | Accurate data flow reduced manufacturing errors. |

| Operational Control | Centralized & Real-Time | Unified dashboard for all operations and finances. |

Read more about their success story: 30% Faster Steel Order Processing with Odoo

When a company grows into multiple sites or product lines, disconnected systems quickly become a bottleneck. This case study examines how Odoo integrates financials, inventory, costing, and operations, creating a unified source of truth that enhances accuracy, automates manual tasks, and enhances decision-making across departments.

Mid-America Manufacturing produces precision metal assemblies for clients across the United States. For years, their quality was in their products, not their processes. Their back office relied on a familiar trio: QuickBooks, Excel, and long email chains. As they expanded to two warehouses and managed over 200 SKUs, this patchwork system began to fail them. Control eroded: product costs became a mystery, month-end reports from different departments conflicted, and the risk of sales tax errors grew with every multi-state order.

The company knew they had outgrown their tools and needed a single platform and a professional approach to adopting it. That’s when they partnered with Glorium Technologies to find a unified solution. Our work on this project is a key example from our portfolio of successful Odoo case studies.

We implemented a tailored Odoo platform in a focused, four-month project with phased milestones to ensure the business kept running smoothly while we replaced their old systems.

We delivered a complete operational hub by:

| Metric | Improvement | Outcome |

| Manual Data Entry | –70% Reduction | Finance team freed from routine updates to focus on analysis. |

| Weekly Costing Work | 15 Hours Saved | Eliminated manual adjustments from QuickBooks. |

| Bank Reconciliation Errors | –90% Reduction | Automated matching cut reconciliation from days to minutes. |

| Budget Overruns | –25% Reduction | Accurate analytic accounting enabled precise budget control. |

| Annual Compliance Risk | $10,000 Saved | Automated sales tax calculations reduced penalty risk. |

Read more about their success story: Mid-America Manufacturer – All Processes Streamlined in One Platform.

For food manufacturers, efficiency hinges on precise planning, traceability, and real-time oversight. This section shows how Odoo helps teams reduce manual coordination, gain control of batch production, track labor transparently, and manage seasonal peaks without compromising product quality or operational speed.

For this Belgian chocolate manufacturer, growth came quickly—and a little faster than their internal systems could handle. The demand was there, the team was growing, and the business was thriving on the outside. But behind the scenes, things were getting increasingly difficult to manage. This is another excellent example from our Odoo case study portfolio.

Every department had its own tools, none of them truly connected, which meant teams were constantly chasing information instead of acting on it.

By the time they reached out to Glorium Technologies, they were spending more than 20 hours every week just piecing together schedules, rebuilding spreadsheets, and trying to make sense of mismatched data. The business was growing—but their systems weren’t growing with them.

Once Glorium Technologies stepped in, the first goal was simple: give everyone a clear, connected view of what was happening inside the company. To do that, we implemented Odoo 18 Enterprise.

The biggest change came from automating the things that were eating up the most time:

| Metric | Improvement | Outcome |

| Weekly Reconciliation Work | 50% Time Saved | Automated workflows freed teams from manual schedule matching. |

| Production Reporting Time | 90% Reduction | Real-time data and dashboards replaced days of manual report assembly. |

| Labor Cost Visibility | 100% Transparency | Costs are now tracked per employee and work order, eliminating estimates. |

| Overall Production Costs | 10% Reduction | Accurate labor and material tracking identified and eliminated waste. |

Read more about their success story: Enterprise Implementation for Food Manufacturer.

For food manufacturers, efficiency hinges on precise planning, traceability, and real-time oversight. This success story demonstrates how Odoo enables teams to reduce manual coordination, gain control over batch production, track labor transparently, and manage seasonal peaks without compromising product quality or operational efficiency.

Our client, a U.S.-based lighting company, had their hands full, juggling custom projects, e-commerce sales, contractor installations, and more. This often happens in manufacturing companies, and we see it a lot in our clients’ cases. The business model is diverse; they observe an increased demand, but are unable to keep up due to outdated tools or scattered documentation.

This situation, common in our Odoo case study reviews, highlights a critical need for integration. The challenge was a lack of connection. They were running a modern, multi-faceted business on tools that couldn’t communicate, leaving them without a single source of truth.

This operational disconnect led them to partner with Glorium Technologies for a unified solution.

We implemented Odoo 18 Enterprise to bring every aspect of their business into one integrated system. We delivered a comprehensive solution by:

| Metric | Improvement | Outcome |

| Inventory Accuracy | Over 90% Increase | Barcode scanning eliminated annual stock losses and shipping errors. |

| Production Defect Rate | 35% Reduction | Integrated quality checks saved rework costs and improved timelines. |

| Monthly Shipping Effort | 20+ Hours Saved | Automated label printing and carrier integrations streamlined fulfillment. |

| Online Sales Conversion | 18% Increase | A modern, integrated e-commerce store improved the customer experience. |

| Accounting Overhead | 15% Annual Reduction | Odoo-QuickBooks sync eliminated reconciliation errors and manual entry. |

Read more about their success story: U.S. Lighting Manufacturer Warehouse Automation.

Retail success depends on synchronized channels, accurate inventory, and clear customer insights. This case study highlights how Odoo unifies POS, eCommerce, stock tracking, and tax compliance—helping retailers reduce overselling, improve margins, and deliver a consistent experience across online and in-store sales.

A UAE-based perfume retailer with a loyal following faced the complexities of modern retail. Operating three physical stores across the UAE and the U.S., plus a thriving online shop, their expansion revealed critical gaps in their systems. Inventory was often a complete guess, manual syncing between online and in-store sales led to overselling, and managing tax compliance across two different countries was a tedious, risky process.

The disconnect between their channels was costly. Teams spent 15-20 hours each week manually updating stock levels and reconciling orders. They were losing approximately $10,000 annually to stockouts and excess inventory, while facing another $2,600 in potential tax penalties.

Seeking a single platform to harmonize their entire business, the retailer partnered with Glorium Technologies.

We implemented Odoo 18 Enterprise to create a central command center for all their sales channels.

We delivered a connected retail ecosystem by:

| Metric | Improvement | Outcome |

| Channel Overselling | 95% Reduction | Real-time sync between online and POS eliminated costly refunds and corrections. |

| Inventory Inaccuracy | 80% Reduction | Automated tracking cut annual losses from stockouts and overstocking. |

| Online Conversion Rate | 15% Increase | A streamlined checkout and accurate stock alerts boosted sales. |

| Tax Compliance Risk | $2,600 Annual Savings | Automated tax calculations eliminated manual errors and potential fines. |

| IT Infrastructure Cost | $10,000 Annual Savings | Odoo.sh cloud hosting removed server maintenance and downtime concerns. |

Read more about their success story: Streamlining Retail Operations with Odoo 18 Enterprise.

Construction firms need real-time coordination between procurement, on-site teams, and finance. This section outlines how Odoo enhances project scheduling, vendor management, material tracking, and budget oversight, enabling construction companies to deliver projects more efficiently, minimize waste, and maintain profitability.

This U.S.-based construction project management company had built a strong reputation for delivering quality work on time. But as their portfolio grew and projects became more complex, the tools they relied on simply couldn’t keep up. Procurement was slow and manual. Inventory was unpredictable. Schedules shifted constantly. And leadership had no real-time view of how budgets were tracking against actual project costs. This scenario is a powerful Odoo business case for industry-specific ERP solutions.

The disconnect between their office and job sites was costly. Project managers couldn’t reliably coordinate material deliveries with their schedules, leading to idle workers and rushed orders. The finance team struggled to track actual costs against budgets, making it difficult to maintain profitability. They needed a unified system to connect procurement, inventory, project management, and accounting.

To build that connected operational foundation, the construction firm partnered with Glorium Technologies.

We implemented Odoo 18 Enterprise as a central platform to synchronize their office and field operations. Our collaborative approach focused on streamlining their most critical processes: purchasing, inventory, and project coordination.

We delivered a comprehensive solution by:

| Metric | Improvement | Outcome |

| Overall Procurement Costs | 18% Reduction | Automated bid comparison enabled smarter purchasing and better rates. |

| Procurement Cycle Time | 2x Faster | Centralized vendor communication slashed approval and coordination delays. |

| Administrative Workload | 30% Reduction | Automated purchase orders and tracking freed the team from manual data entry. |

| On-Time Project Delivery | 23% Improvement | Reliable material availability and coordination reduced schedule overruns. |

Read more about their success story: Construction Project Management Odoo Implementation.

Restaurant chains face constant pressure to maintain consistency while controlling costs. This section explains how Odoo supports multi-location operations through centralized POS, accurate food costing, integrated accounting, smarter scheduling, and loyalty programs that keep guests returning.

This U.S. restaurant brand built its reputation on fresh, healthy meals served quickly — and customers loved it. With three busy locations and demand increasing, the chain found itself in a familiar growth challenge: the food was great, the customer experience was strong, but the behind-the-scenes operations weren’t keeping up. This successful project is a prime example from our food and beverage Odoo ERP case studies.

Each restaurant was running its own POS system. Ingredients were tracked on spreadsheets. Managers were juggling shift planning and payroll manually. And because recipes weren’t costed in real time, it was nearly impossible to understand which dishes were profitable and which were quietly eating into margins.

As sales rose, these gaps started to hurt consistency, profitability, and even compliance. The company needed a system that would scale with them — not hold them back.

To help the restaurant chain scale smoothly, we implemented Odoo 18 Enterprise on Odoo.sh, connecting all core operations into one platform:

| Metric | Improvement | Outcome |

| Food Waste | 22% Reduction | Expiry alerts and demand-driven purchasing turned waste into direct savings. |

| Overall Revenue | 18% Increase | Real-time cost data enabled dynamic menu pricing and profitability strategies. |

| Managerial Reporting Time | 50% Faster | Automated, real-time dashboards replaced days of manual data compilation. |

| Returning Customers | 5% Increase | POS-integrated loyalty programs and targeted promotions boosted retention. |

| Workforce Scheduling | 28% Faster | Digital shift planning and mobile tools streamlined staff management. |

Read more about their success story: Odoo Implementation for Food & Beverage Company.

As dining evolves across dine-in, delivery, and events, restaurants need technology that keeps everything connected. This success case showcases how Odoo modernizes online ordering, banquets, staffing, and kitchen coordination, giving restaurant groups the tools to grow quickly without operational friction.

With three busy locations, a centralized kitchen, a warehouse, and a full range of dine-in, takeout, delivery, and banquet services, this Dubai-based restaurant is a hub of activity. The successful business, however, was struggling with fragmented operations and a lack of a branded online ordering system, which constrained their growth in a competitive market.

Paper-based POS tickets slowed down the kitchen during peak hours. Inventory was hard to track, leading to unnecessary spoilage. Banquet bookings sat inside spreadsheets (with a constant risk of double bookings). Staff scheduling took hours and still didn’t reflect real demand. And without a branded online ordering site, a big chunk of potential revenue was going through third-party delivery platforms.

To streamline their operations and fuel their expansion, the restaurant group turned to Glorium Technologies.

To fix the fragmentation, we implemented Odoo 18 Enterprise on Odoo.sh, connecting every part of the business into one smooth, data-driven operation.

Here’s how the system transformed their operations:

| Metric | Improvement | Outcome |

| Peak-Hour Order Processing | 25% Faster | Tablet POS and KDS integration reduced errors and wait times. |

| Direct Online Orders | 25% Increase | A branded ordering portal reduced reliance on third-party apps. |

| Banquet Inquiry Conversion | 80% Improvement | Automated follow-ups and online booking eliminated missed opportunities. |

| Operational Costs | 15% Reduction | Reduced food waste and optimized labor scheduling lowered overall costs. |

| Financial Reconciliation Errors | 90% Reduction | Automated QuickBooks sync saved over 10 hours of weekly manual work. |

| Customer Retention | 12% Increase | CRM-driven loyalty programs and personalized offers boosted repeat visits. |

Read more about their success story: Restaurant Operations, Online Ordering & Banquets.

As you’ve seen in these success stories, the challenges change from one industry to the next, but the solution often has the same name: a unified platform.

Across eight different industries, Odoo 18 Enterprise delivered a consistent result: replacing manual work and data silos with automated control. For some, the goal was to cut quotation time in half, and for others, to eliminate stockouts; however, the outcome was always greater efficiency and clearer insight.

Such versatility is possible because Odoo is not a rigid system; it’s a scalable, modular foundation that works just as well for a single warehouse as it does for a multi-country operation.

The proof is in the specific details:

Individually, these wins appear industry-specific—but together, they highlight Odoo’s greatest advantage: the flexibility to adapt to any workflow without requiring the business to alter its operations.

Solving the issues we’ve encountered in these case studies required a unified system; however, choosing the right partner for Odoo implementation services can make the difference between simply installing software and fully transforming how your business operates.

The results of our eight Odoo 18 Enterprise implementations speak for themselves: Glorium Technologies delivers systems that work in real life, for real teams, under real operational pressure.

Our clients span the manufacturing, food production, retail, restaurant, construction, and project-driven business sectors—yet every project shared the same outcome: streamlined processes, real-time visibility, and measurable ROI.

We’ve helped a steel manufacturer cut quotation time by 50%, a chocolate producer track labor with precision, a lighting manufacturer eliminate inventory mismatches, and a perfume retailer reduce overselling by 95%. In the F&B sector, we enabled a healthy restaurant chain to reduce food waste by 22% and helped a Dubai restaurant group speed up service and manage banquets seamlessly. For a construction project management firm, we simplified procurement, linked project costs, and accelerated delivery timelines.

What sets Glorium apart isn’t just technical expertise—it’s our methodology. Every engagement begins with deep discovery sessions, where we map how your business actually works. We design configurations around your reality, not generic templates. Our phased rollouts ensure smooth adoption, while our training programs empower your teams from day one. And once the system goes live, we stay involved—offering ongoing optimization, support, and the flexibility to scale the solution as your operations evolve.

If you’re ready to get the same level of efficiency, accuracy, and scalability in your own operations, we’re here to help. You can request a customized demo or an intro call with our Odoo experts to get answers to your specific questions and get guidance from our team.