Why They Chose Glorium Technologies

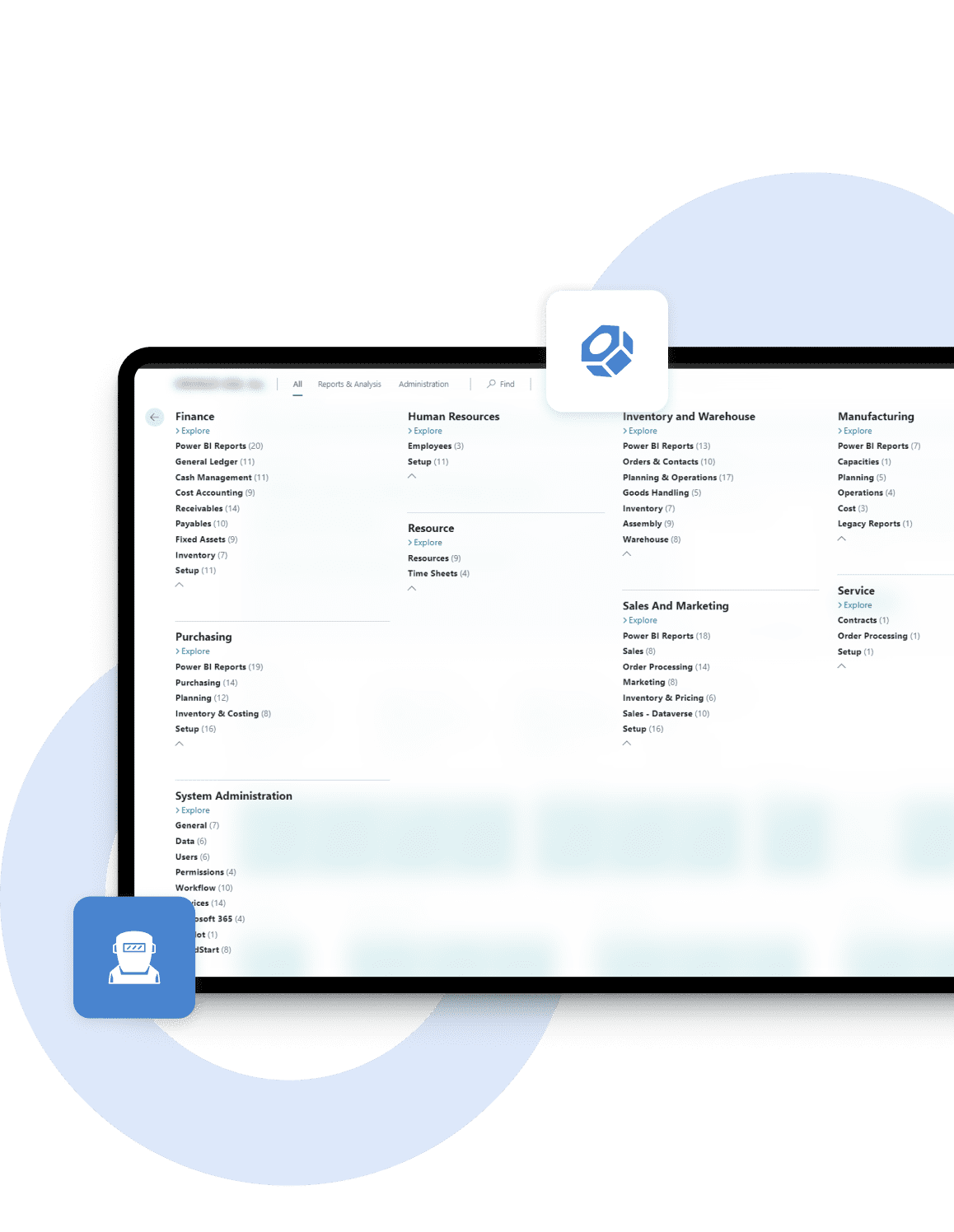

What Set Our Microsoft Dynamics 365 Business Central Implementation Apart

- End-to-end process analysis with the discovery phase

- Clear migration roadmap to Microsoft Dynamics 365 BC

- Future-state (“to-be”) process design

- High functional coverage out of the box

- Modular expansion without disrupting existing workflows

The Solution

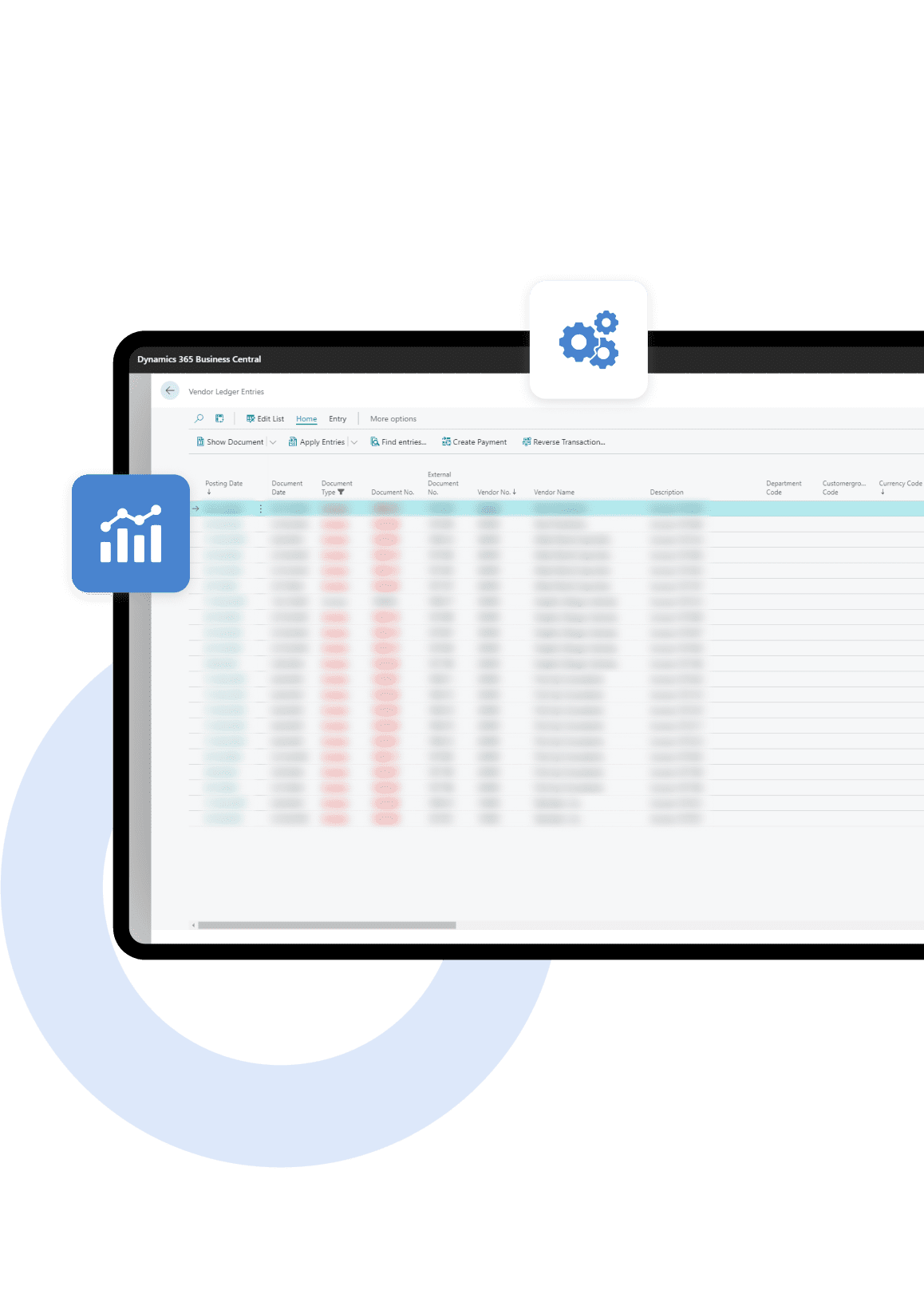

Building a Unified Platform with a Two-Phase Implementation

- Finance and general ledger

- Fixed assets and reporting

- Sales and customer orders

- Purchasing and vendor management

- Production and shop floor control

- Inventory and warehouse management

Implementation Approach

A 16-Week Journey and a System Rollout Focused on Real User Needs

Phase 1: Planning & Core Rollout

- Discovery workshops to map current (“as-is”) processes across finance, production, inventory, and purchasing

- Design of future-state (“to-be”) processes aligned with Business Central best practices

- Configuration and rollout of Finance, Sales, Purchasing, Production, Inventory, Fixed Assets, and Reporting

- Data migration from legacy accounting and warehouse systems into BC

- Initial dashboards for management reporting

Phase 2: Process Refinement & User-Driven Enhancements

- Collection of user feedback from planners, accountants, and production supervisors

- Fine-tuning of workflows, approval rules, and document flows based on real operational needs

- Implementation of inventory analysis routines and replenishment logic that consider open orders and demand trends

- Optimization of cost allocation and overhead tracking to improve project profitability insights

Phase 3: Training & Continuous Improvement

- Role-based training for finance, warehouse, and production teams using real-life orders and materials

- Coaching sessions for key users to build internal champions and reduce dependency on external support

Business Value

What a Unified System Actually Delivers

Questions You May Have

Is Microsoft Dynamics 365 Business Central customizable for unique manufacturing needs?

Yes. Microsoft Dynamics 365 Business Central ERP is a highly customizable system. Out-of-the-box functionality is beneficial, but can be extended through integrated apps or tailored configurations. With the right Microsoft Dynamics 365 Business Central implementation partner, you can easily adapt it to complex manufacturing environments.

How much does Dynamics 365 Business Central cost?

The Microsoft Dynamics 365 Business Central cost is based on a predictable per-user, per-month subscription model. There are different license tiers (Essential and Premium) to match job functions, and pricing can vary slightly by region and partner.

Is Dynamics 365 Business Central a CRM or ERP?

Microsoft Dynamics 365 Business Central is a comprehensive, cloud-based ERP. However, it does include integrated CRM-like capabilities for managing sales contacts and opportunities. The system consolidates core operational functions (finance, manufacturing, supply chain, etc.). For a full Microsoft Dynamics 365 Business Central overview, think of it as the central operational and financial brain of your business. In contrast, a CRM is more specialized for the sales and marketing funnel.

Will implementing a new ERP disrupt our current operations for months?

Not necessarily. A well-planned Microsoft Dynamics 365 Business Central implementation is designed to minimize disruption. Partners like Glorium Technologies use a phased approach, often rolling out core financials and inventory first before moving to more complex areas like production. The key to minimal disruption is thorough planning, clear communication, and role-based training.

Can we reduce our inventory costs without risking material shortages?

Yes. This is why many manufacturers turn to Microsoft Dynamics 365 Business Central ERP. The system provides data intelligence to find the optimal balance. With it, you can:

- Set minimum stock levels and reorder points based on actual usage patterns

- Differentiate between fast and slow-moving items to adjust the purchasing strategy

- Tie inventory purchases directly to firm customer orders and realistic forecasts