Core Capabilities Delivered with Odoo Logistics

We set up Odoo to mirror the client’s real-day-to-day workflow across warehouse facilities, dispatch, and finance. The focus was to keep inventory, shipment status, and billing aligned in one system, so teams spend less time on handoffs and more time moving shipments forward.

- Multi-warehouse inventory control with real-time stock updates and replenishment logic

- Warehouse execution improvements, such as wave picking and cross-docking, to speed fulfillment and reduce handling

- Shipment visibility workflow, so dispatch and customer-facing teams could track progress without chasing updates across tools

- Finance alignment with logistics events, improving cost tracking, and reducing delays in reporting

- Where needed, custom integrations with external services, built with maintainability and upgrade planning in mind

Fully Connected Operations Powered by Odoo Logistics

The Odoo implementation improved daily control across warehouse facilities, dispatch, and finance. Instead of “status-by-asking,” teams worked from one shared operational picture, with cleaner inventory data, clearer shipment progress, and faster financial follow-through.

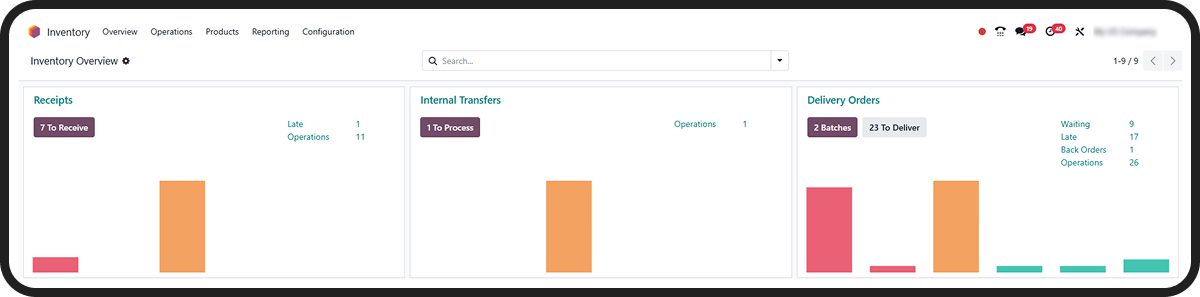

Warehouse and Inventory Operations

Odoo’s Inventory and warehouse workflows supported real-time updates across locations and reduced manual steps in receiving, picking, internal moves, and outbound preparation. With fewer handoffs and less rework, warehouse execution became more consistent and easier to manage across multiple facilities.

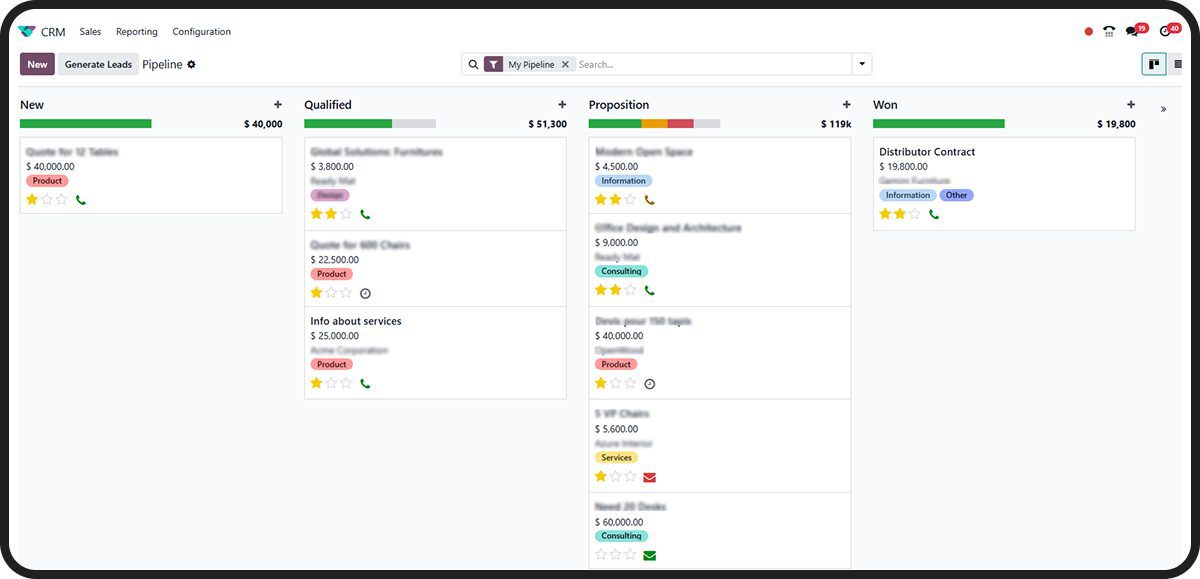

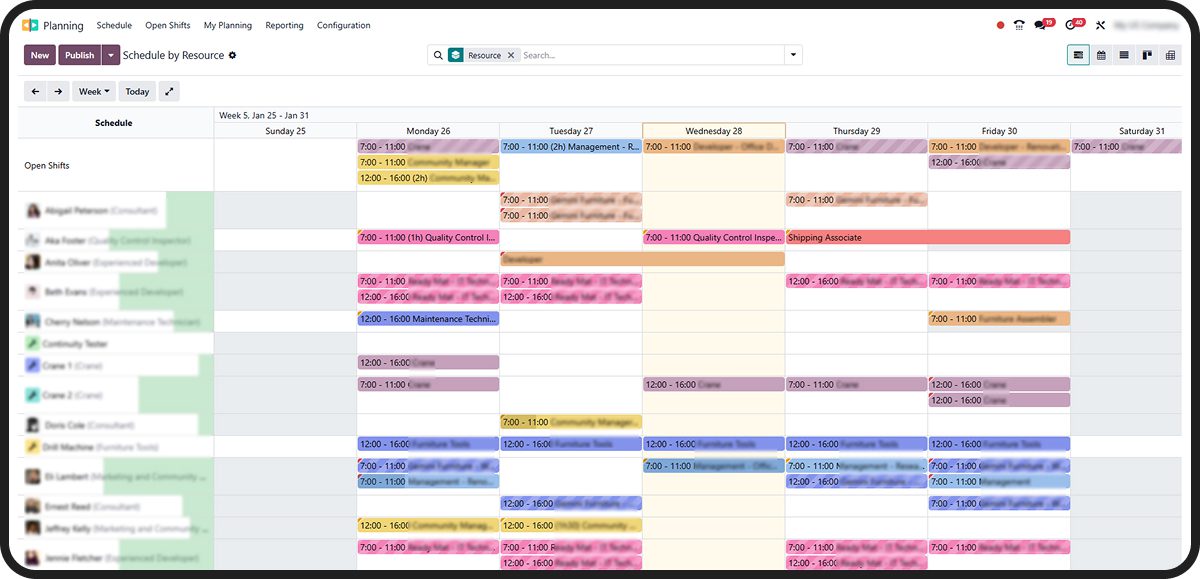

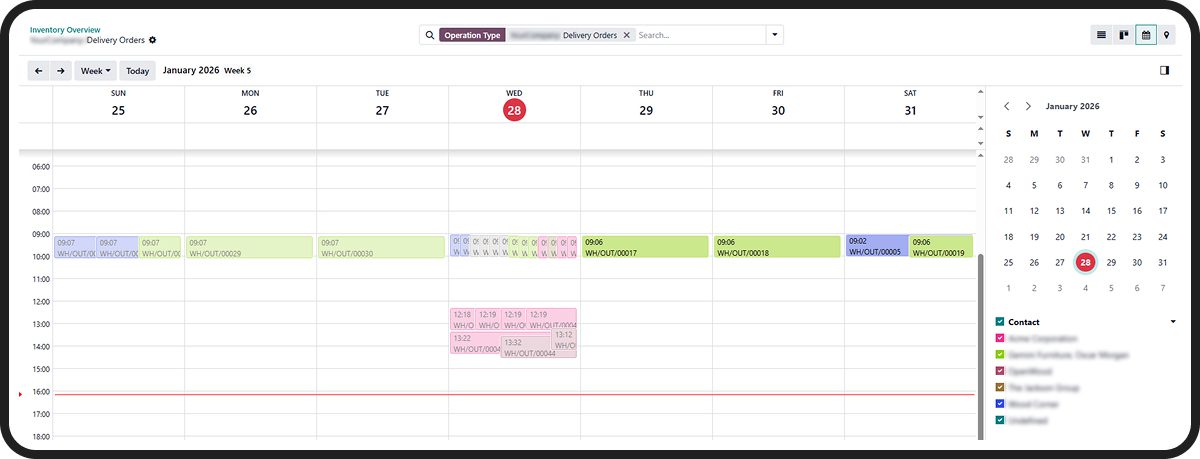

Shipment Tracking and Daily Logistics Coordination

By centralizing shipment and delivery information, dispatch and support teams gained a more reliable tracking flow across warehouses and routes. This reduced the time spent chasing updates and helped teams react earlier when a delivery was blocked or at risk.

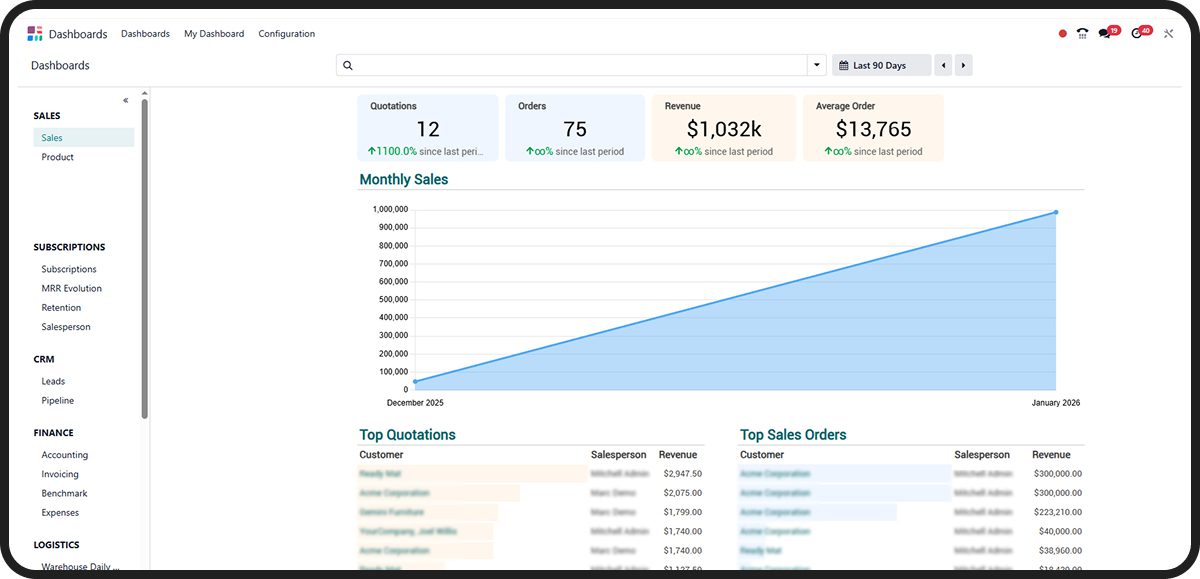

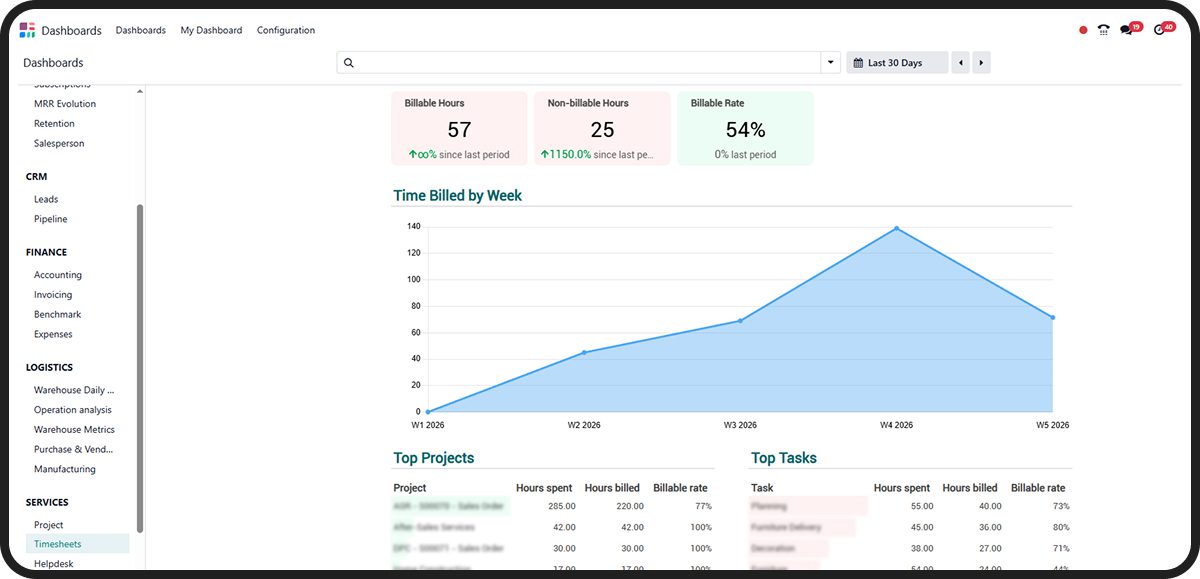

Billing, Invoicing, and Cost Control

Odoo’s accounting and invoicing workflows stayed aligned with operational events, so finance no longer had to reconstruct shipments after the fact. Reporting became more timely, and cost tracking improved, especially for complex, multi-step deliveries where margin control depends on accurate inputs.

A Phased Rollout That Fits SME Logistics Teams

Our implementation approach follows a structured four-phase rollout. It keeps control high and disruption low during daily runs. For this client, we delivered the project in 18 weeks, split across these four phases.

Phase 1: Discovery and Planning

- Workshops with warehouse, dispatch, and finance stakeholders

- Workflow mapping for inbound, storage, picking, outbound, and billing

- Scope definition for Odoo modules and reporting needs

Phase 2: Configuration, Customization, and Integrations

- Multi-warehouse setup and core logistics workflows

- Data preparation and migration planning (products, locations, partners, rates)

- Custom extensions and integrations where standard Odoo flows needed alignment

Phase 3: Training and Operational Optimization

- Role-based training for warehouse, dispatch, and accounting teams

- Hands-on scenarios based on real daily runs and exceptions

- Workflow tuning to reduce manual steps and improve control points

Phase 4: Testing and Go-Live Support

- End-to-end testing across warehouse-to-delivery-to-invoice flows

- Cutover planning and guided go-live execution

- Post-launch support to stabilize operations and refine processes

Faster Cycles, Better Control, and a Clear ROI Path

40–60% Less Manual Work in Daily Operations

By integrating warehouse execution, dispatch workflows, and finance into a single system, the team reduced duplicate data entry and the need for constant “status checks.” Routine tasks moved from spreadsheets and messages into Odoo flows, reducing errors and freeing time for exception handling and customer service.

~30% Shorter Cycle Times Across Warehouse and Dispatch

Workflow automation reduced handoffs between roles and locations. With clearer task ownership and fewer waiting points (for confirmations, inventory updates, or approvals), picking-to-dispatch and dispatch-to-invoice cycles became noticeably faster and more predictable.

Improved Real-Time Visibility for Faster Decisions

Inventory, shipment status, and financial signals stayed aligned in one place. That made it easier to spot bottlenecks (missing stock, late outbound loads, stalled deliveries) and take action early before delays escalated into penalties.

ROI in 12–18 Months Through Lower Overhead and Better Control

The client achieved a practical payback window by reducing manual labor, avoiding preventable operational mistakes, and improving cost tracking for shipments and warehouse activity. Over time, the same setup also supports growth: new warehouses, routes, and carriers can be added without rebuilding the process from scratch.