Optimize Stock Levels with Odoo Inventory Solutions

Manufacturers lose millions every year because of poor inventory control. Materials expire on shelves, production halts due to missing parts, and overstocked items eat up warehouse capacity. This is more than a logistical issue—it’s a strategic setback stemming from outdated, fragmented systems that rely on spreadsheets and manual inputs.

Odoo inventory management software changes the equation. It connects the inventory app with up-to-the-minute sales and production data, helping you respond faster while eliminating costly delays and overordering. Not only can you save time by reducing manual stock tracking, but you can also improve strategic planning accuracy. A 20% increase in your team’s productivity can translate into thousands of dollars in savings. The result: leaner operations, reduced waste, lower expenses, and better decisions powered by live data.

Content

Around 62% of companies suffer revenue loss due to inventory management failures, largely due to fragmented systems and limited visibility. It is not surprising as 67.4% of warehouse managers make journal entries in immortal Excel, which remains the default for 75% of late-stage adopters.

Odoo’s inventory valuation module introduces a new level of control to stock management by automating replenishment based on actual demand. Your warehouse employees don’t need to manually track product availability and wait for someone to flag a shortage. Whether for managing raw materials or finished goods, the ERP system is the only thing you need to see fewer interruptions on the production floor and gain tighter control over spending.

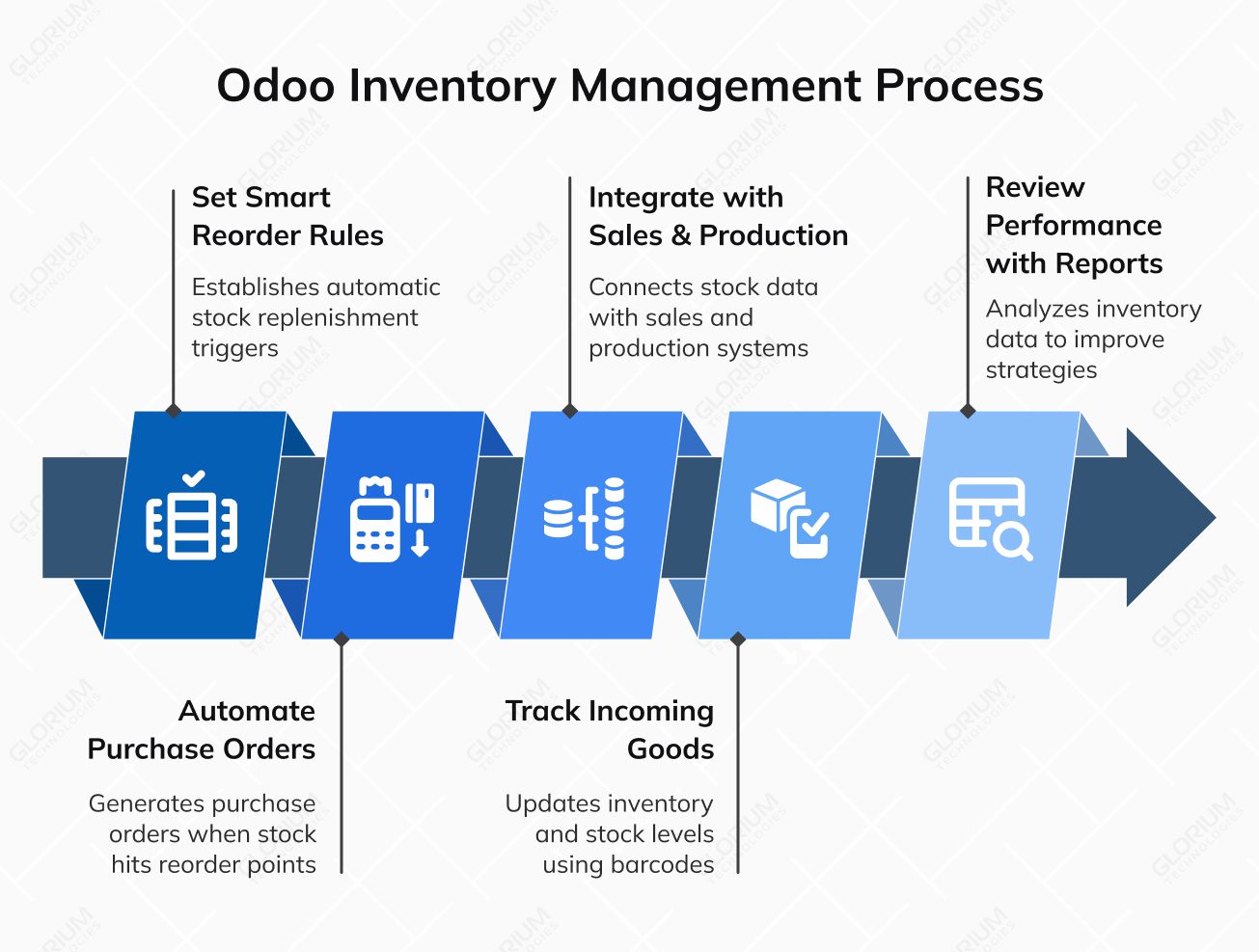

If you want to make Odoo’s automated inventory system work for you, follow the guidelines below.

Odoo’s inventory app allows you to define smart replenishment points using real-time stock valuation and inventory levels. You can configure automatic inventory valuation based on FIFO, LIFO, or average cost methods, depending on your product categories. The system responds instantly by triggering a purchase order or internal transfer based on live data and preset figures.

Your team members can benefit from reduced manual intervention, especially with high-turnover items where timely replenishment can make a difference. By assigning units of measure and storage locations per product, they can improve accuracy while reducing discrepancies. The stock valuation dashboard makes it easy to monitor inventory value fluctuations instantly.

For example, if a fast-moving product in a key category runs low, the system automatically generates a purchase order, preventing delays in fulfillment. You can track the receipt using batch or serial numbers. This automation supports better forecasting and helps keep overstocking or understocking at bay.

Odoo ERP generates POs automatically the minute stored product levels hit the reorder point. The system references vendor price lists, adjusts for lead times, and selects suppliers based on predefined data. Serial numbers and batch numbers can be linked directly to the receipt process, improving traceability.

If you manage multiple storage locations and product categories, automation can become your business-saver as it reduces delays and human error. With POs and a clear configuration in place, the average cost and standard price of products are continuously updated, and all transactions are synced with the accounting app, updating the stock valuation account for accurate financial reporting.

You can track POs in the app with detailed logs of valuation, supplier delivery performance, and fulfillment timelines. Finally, you can wave bye to spreadsheets or delete never-ending email chains—everything is centralized, traceable, and optimized for speed and accuracy. It also ensures that procurement aligns with current warehouse goods valuation methods.

Odoo connects stock data directly to sales orders and the manufacturing resource planning system. Thus, your team can easily forecast demand and avoid oversupply due to outdated reports. As sales orders are confirmed, the ERP solution automatically adjusts inventory counts.

Dynamic data updates make stock value tracking more transparent, while the app ensures consistency in units of measure and storage location usage. The stock valuation dashboard provides visibility across departments – from purchasing to accounting – helping your teams coordinate more effectively. They can react instantly to inventory and sales activity, reducing the number of last-minute changes and guaranteeing products are ready when customers expect them.

Accuracy with barcode scanning, lot and serial number tracking, and live inventory monitoring is what Odoo can enhance. Once goods are received, the system updates the inventory valuation report and adjusts stock levels instantly. This level of tracking allows for lowering manual stock counts drastically and improving traceability for every batch meanwhile.

Storage locations are automatically updated based on predefined rules, reducing confusion and improving internal logistics. Warehouse staff can access product data, receipts, and movement history from the dashboard, improving response time by 86%. The app allows you to compare expected vs. actual receipts and track inconsistencies over time.

If you are searching for a comprehensive suite of reports that include inventory valuation, stock aging, turnover rates, and product movement, look no further than Odoo. It makes for a treasure trove of these insights so that you can identify slow-moving stock and develop smarter replenishment strategies. Its inventory valuation report consists of configurable filters, which you can adjust to determine product category or storage location in no time. Thus, you can make data-backed financial decisions that align with broader business goals.

Nothing speaks volumes about the ERP system’s advantages as its real-life results, backed by numbers. The backstory: A mid-sized manufacturer relied on fragmented systems, spreadsheets, and manual stock counts, to name a few. As there was misalignment between inventory value and actual levels, they had to deal with constant over-ordering, and delayed financial reporting. As problems snowballed, the business faced financial distress. Odoo’s implementation became a part of the crisis management plan.

After switching to Odoo, the company gained access to automatic inventory valuation, barcode-based tracking, and integrated purchasing. Within 2 months, they managed to:

Moreover, they implemented FIFO for key product categories and linked all data to their accounting app so that financial reports started reflecting actual stock value without manual reconciliation. The result was not only operational clarity but financial accuracy at every level.

Keeping your stock records accurate isn’t just about profitability and strategic planning; it is a compliance requirement. You must go all out to ensure you are audit-ready when authorized people come. While manual reconciliation and after-the-fact adjustments can let you don’t, Odoo can’t. It ensures every stock movement is financially accounted for—from initial receipt to sale. Each transaction is automatically tied to a stock valuation method of your choice and immediately reflected in the account within the app.

Auditors don’t just want numbers—they want traceability. Odoo inventory provides full audit trails for inventory transactions, valuation changes, and accounting entries. Product-level detail, batch and serial tracking, and timestamped movements across storage locations will be all captured, leaving no room for ambiguity.

The valuation report offers a breakdown of current and historical values, segmented by product category or location, which supports both internal audits and external financial reviews. When you have ERP at your fingertips, you no longer need to patch together data at the end of a period. Odoo inventory can shorten audit cycles and give your financial teams a foundation they can stand behind.

Managing inventory across disconnected tools becomes a roadblock as you start scaling your business. Not only do errors creep in, and stockouts happen all the time, but forecasting turns into pure guesswork, too. You need a tool that can smoothly adapt to your existing setup and grow alongside your operations. That’s what makes Odoo the best bet for manufacturing enterprises of all sizes. Its modular configuration and built-in integrations bring all your activities under the same roof – from warehouse to accounting.

Once you decide to put Odoo inventory to good use, come to Glorium Technologies, its official partner. We know the ins and outs of the ERP system, so its implementation will be a cinch. If a standard setup doesn’t speak to you, our specialists can customize it the way it fits you.

Team up with Odoo experts who know how to turn features into real results. Schedule your free 30-minute talk – no pressure, no cost.